Turntable

My initial idea for final project was to make a audio message box for my grandma. However, I have not figure out build an app for recording and sending message to a cloud service. Also, I had many issues with DAC. I decided to change my idea and start from something more feasible at this stage. My grandma is a music fan, so I am making a vinyl record player. Also because she likes to listen to music and fall asleep, I decided to make this player sense to the light. It turns off automatically when lights off.

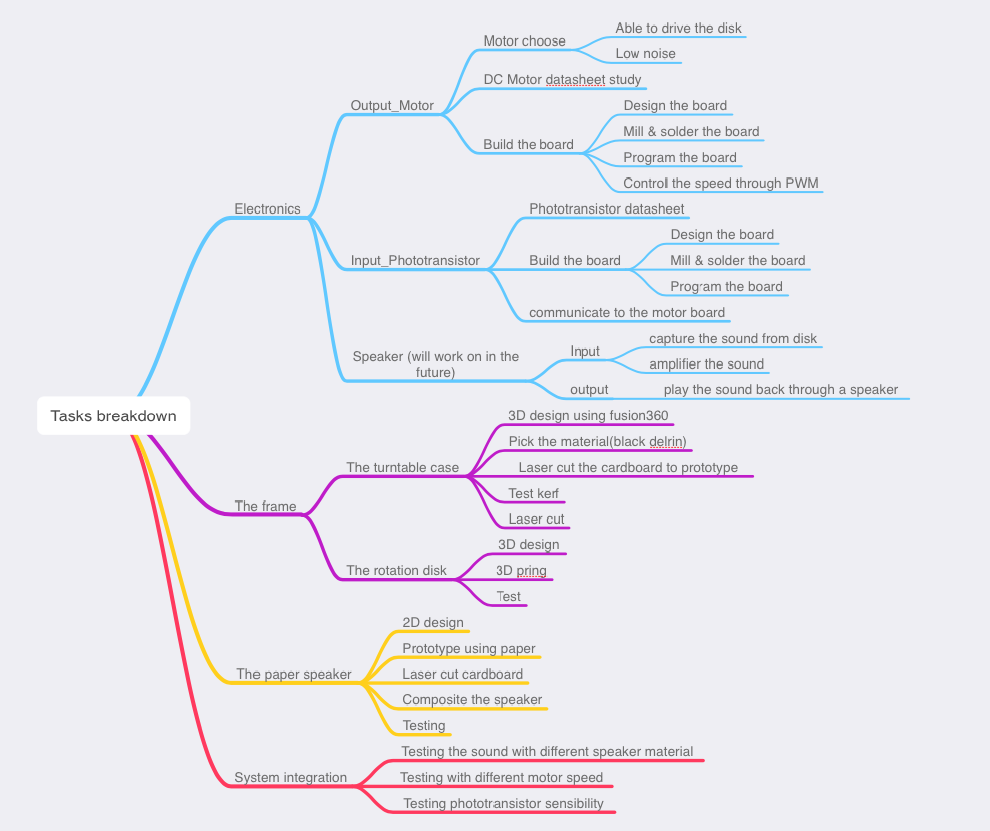

Project Breakdown

Breakdown of my project process.

Electronics

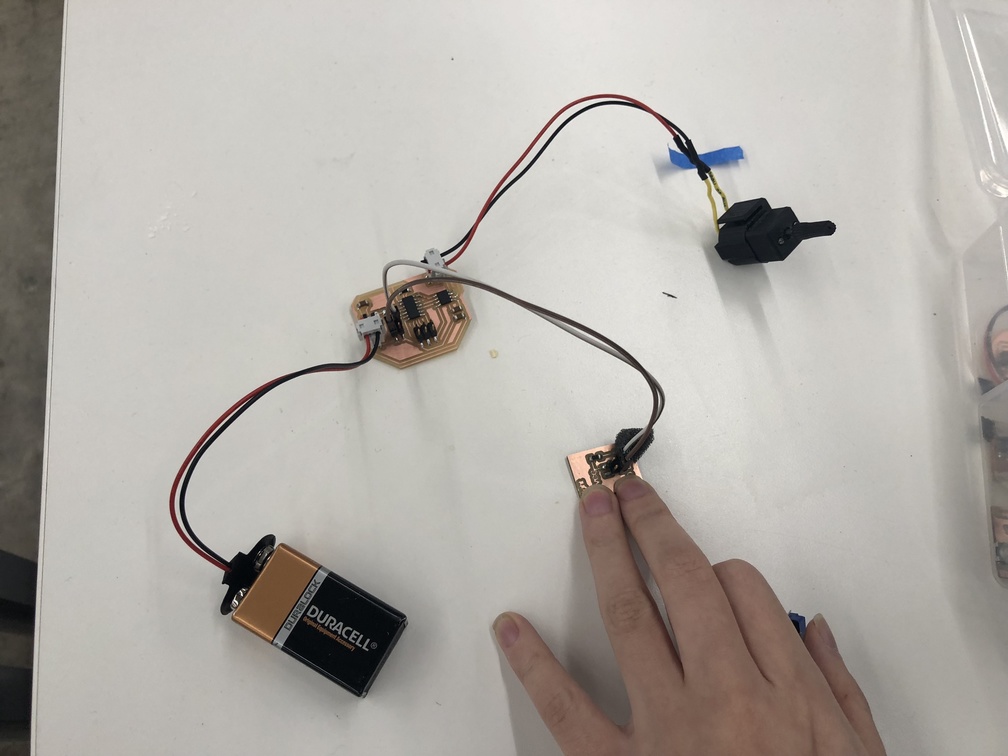

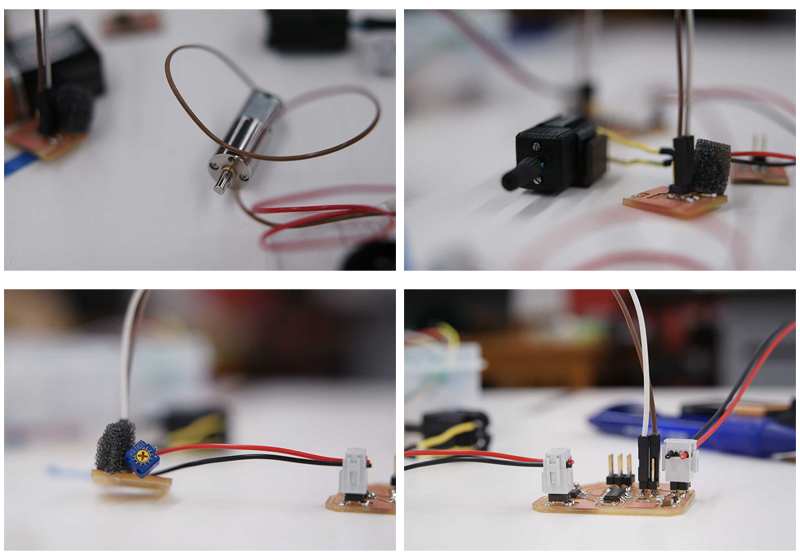

I have been working with microphone and speakers for the past a few weeks. But the most important module for my player is DC motor and input is light. I started by choosing the right motor. Joe told me I need that I need to use gear motor since i am driving the disk directly. Rob helped meI tested the speed of different motor.

This black motor is the motor I chose. It can ran pretty fast under 9 voltage and then I can use PWM to adjust its speed I designed my board based on Neil’s DC Motor board and added a 2*2 PIN for connecting phototransistor. I also used a potentiometer resistance with 100k OHM at the largest. I could adjust the light sensitivity by adjust resistance.

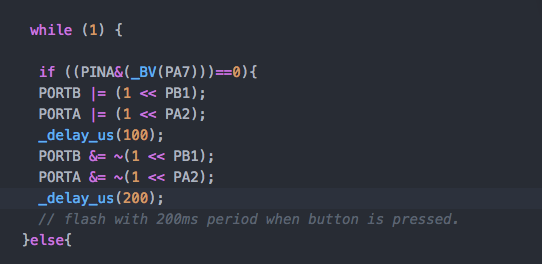

PWM:The code I am using the adjust the speed.

Speaker

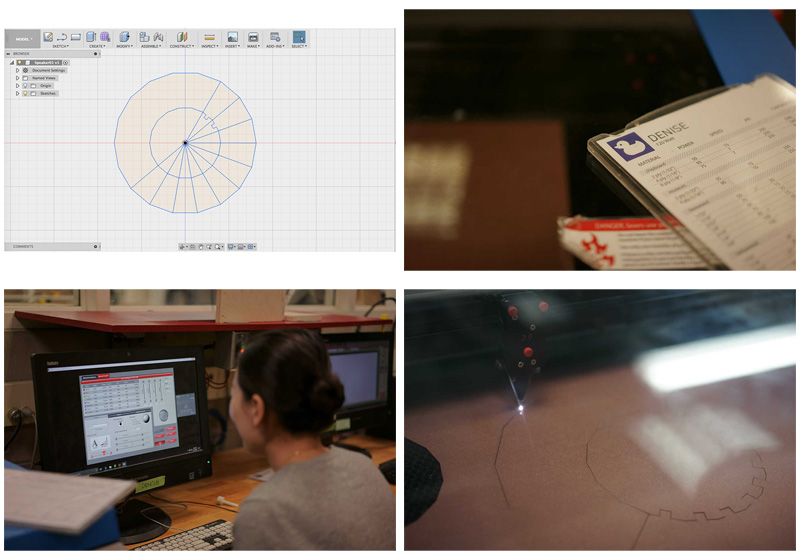

I decided to build a decagon speaker, and laser cut it.

I tried to composite the cardboard. It looks nice but didn’t sound well.I made another larger one.

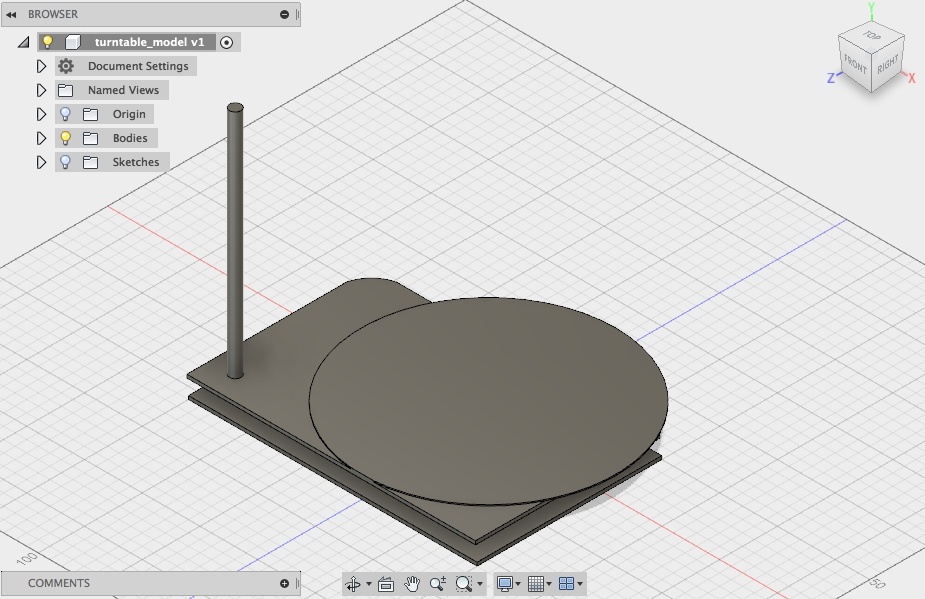

I designed the model using fusion360. I found a few very nice Delrin piece and Joe told me i could laser cut them.

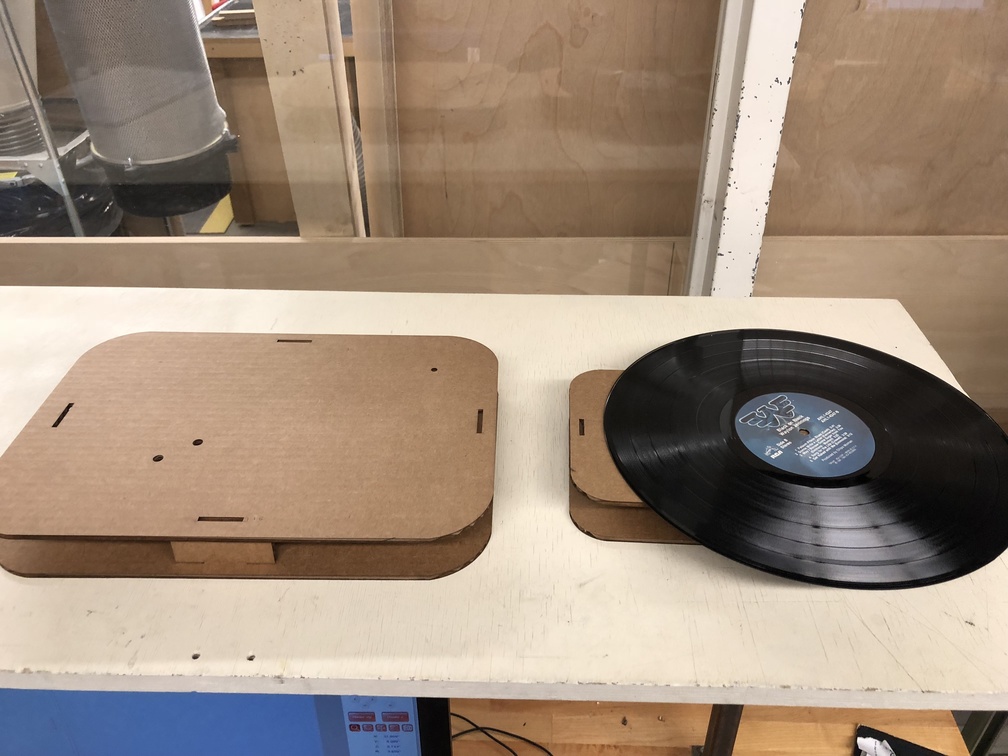

I started by cutting cardboard and prototyped it. I found the perfect size after trying twice.

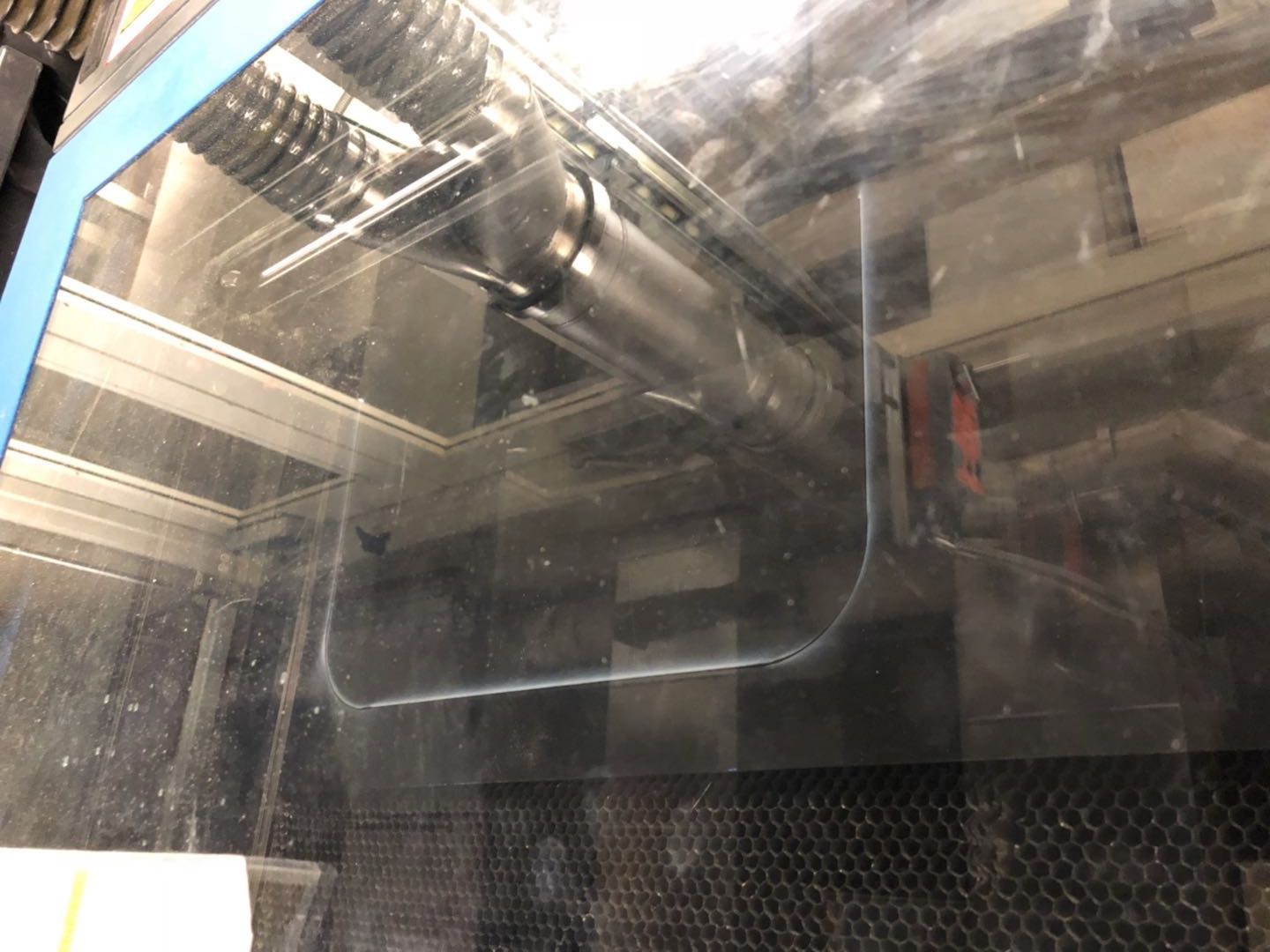

I did a test cut on Delrin and tried to figure out whether my kerf works. I found that the became larger under laser cut temperate becuase Delrin shranked under high temperate. Therefore, I had to try a few more times to get a perfect fit. Then, I started the offical cut.

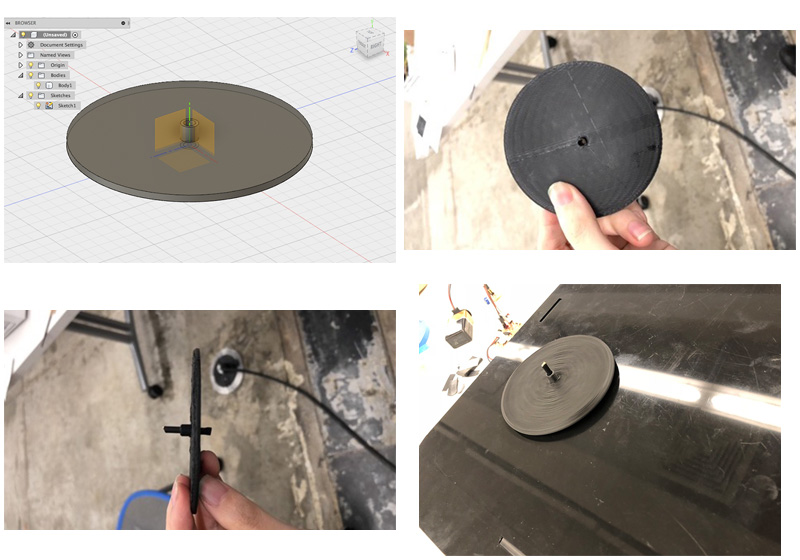

I also decided a disk to put on motor to make my vinyl record balance .

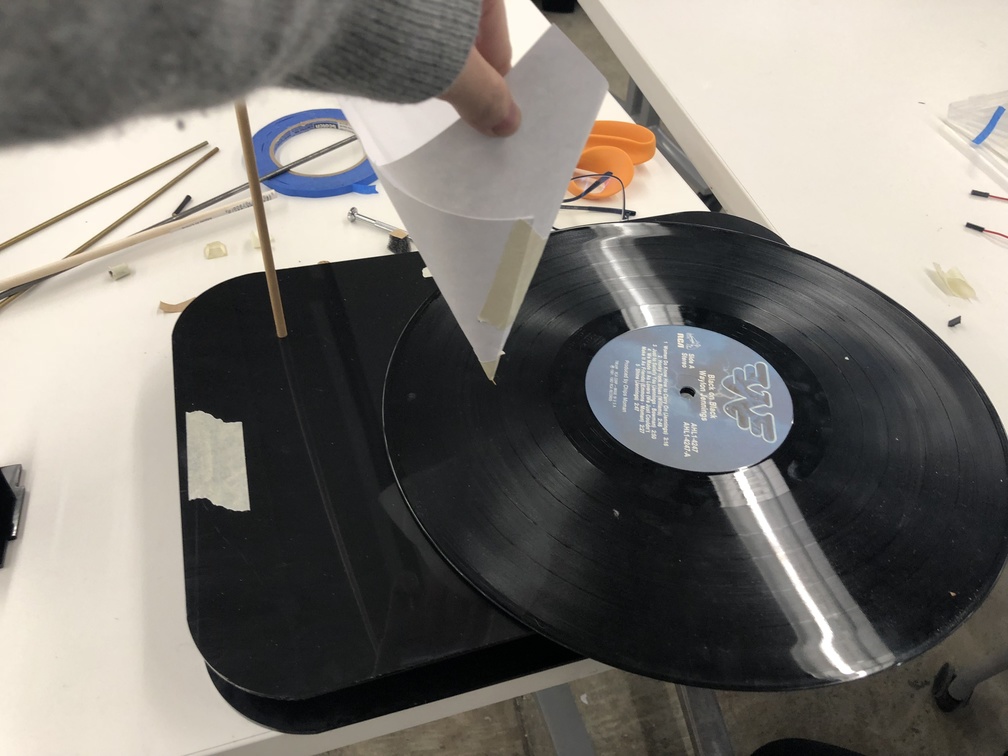

Testing with paper. I found that paper works better than the cardboard speaker I made. Therefore, I deciede to go with paper.

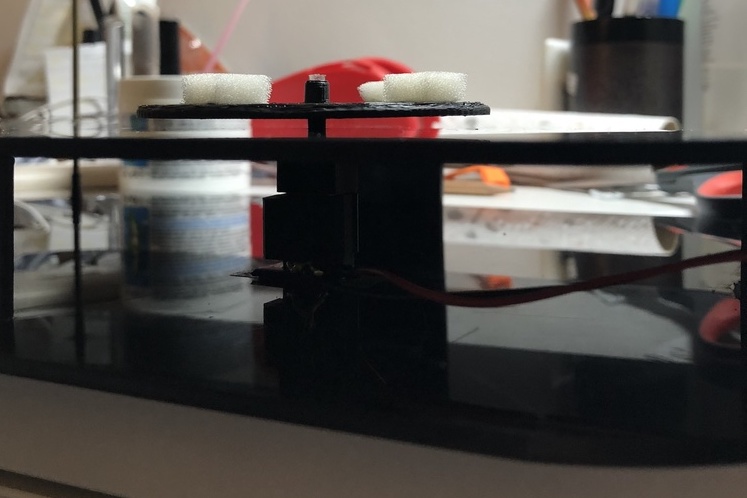

I tried multiple ways including put different size of rubber between motor and 3D printed disk and put a few sponges between disk and record. Finally,I was able to balance the record.

Download Bill of Material learnt

Lesson learnt

- Plan Set clear small milestones. Getting small milestone done is more important and realistic than accomplishing something big and perfect goal. This is very important for getting things done on time. KEEP MAKING PROGRESS.

- Datasheet Read datasheet. I was overwhlemed initally by how much information was in there and didn't even think about read them carefully. However, I found them to be very useful later on. I wish that I read more carefully at the beginning.

- Prototyping Always prototype with each module you are making.

- Setup Get to the presentation place early, do not waste time on making final adjustment somewhere else than the presentation place. I was able to play the music very well and failed at the presenation since I didn't get enough time to do the final adjustment there.

Acknowledge

Thanks Rob, all the TAs and all my Harvard session classmates. Of course, thanks Neil for the course. Coming from a background with no electronical engineering and design, I really appreciate this opportunity. I want to design more preojct based learning curricumlum for more kids based on my own learning in the future. Meanwhile, I can't wait to start my life-long How to make almost class! My first project will be finishing my initial final project idea below.

Photo credited to my friend Hongyi Li.

NEXT PROJECT: MY Original Idea

Important components

- Communication: Recording the message and send to internet.

- Audio recording: Record at least 30 seconds audio message.

- Audio playing Play at least 30 seconds audio message.

- Materal: gel