13. Composites

- Design Challenge: design and fabricate a 3D mold (~ft2)and produce a fiber composite part in it, with resin infusion and compaction

- Software: Fusion360, V-carve

- Date Completed: 12.12.17

Design and fabricate a 3D mold

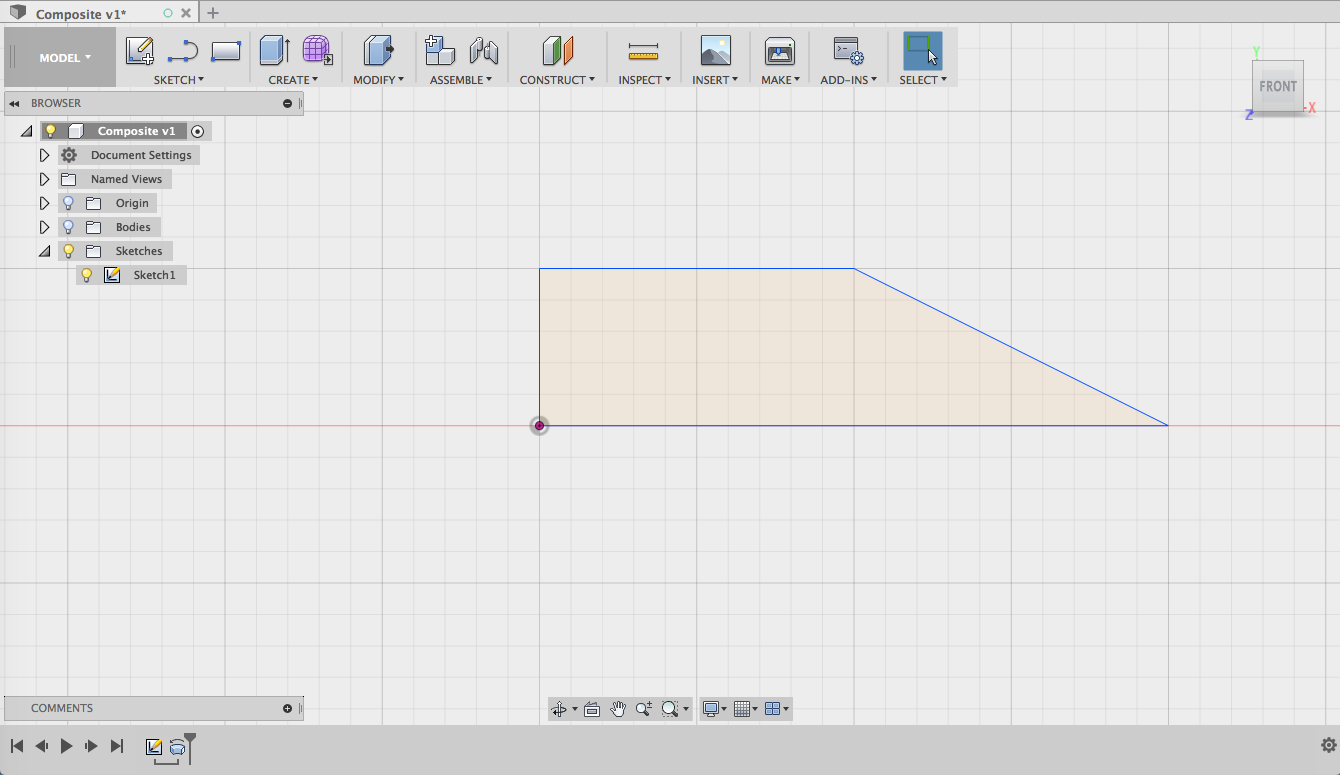

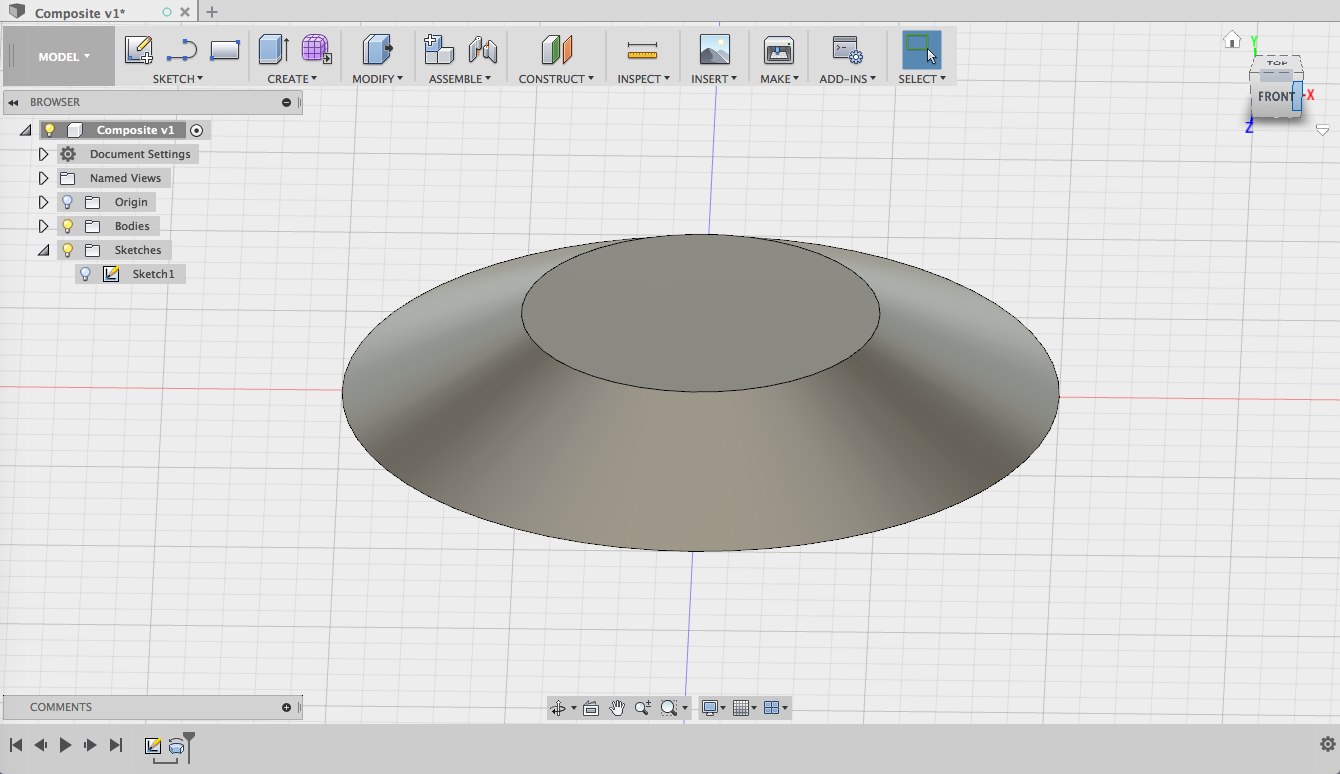

This week's task was to design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it. I have never worked with composite before, so I decided to create something simple first. I decided to make a fruit plate. I used Fusion360 to design the mold.

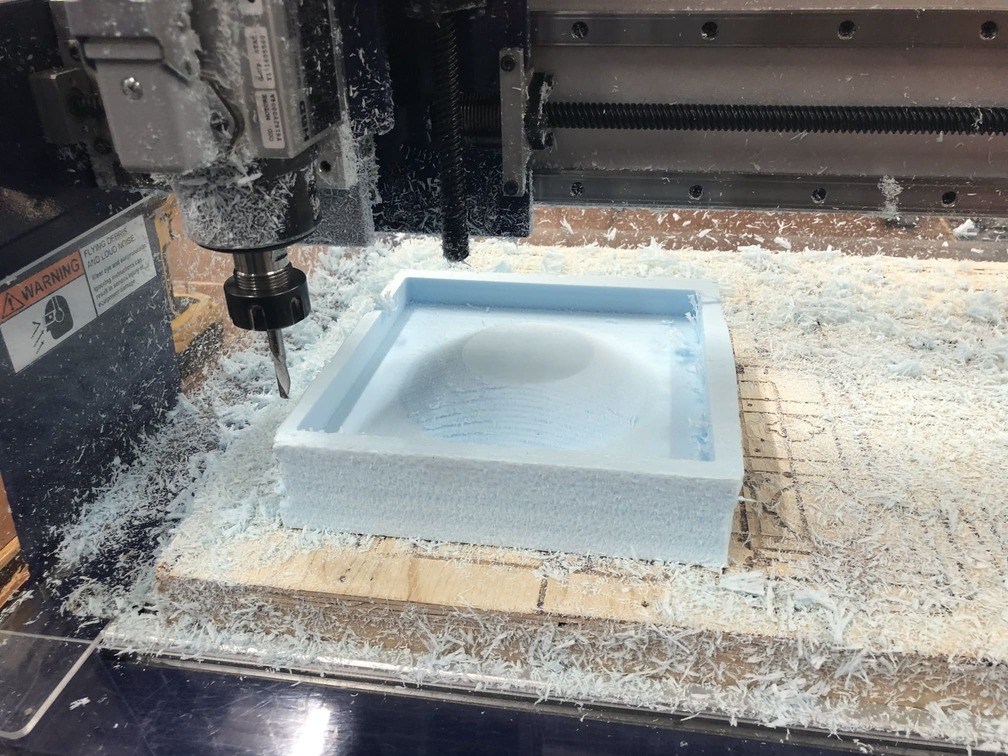

3D Mold

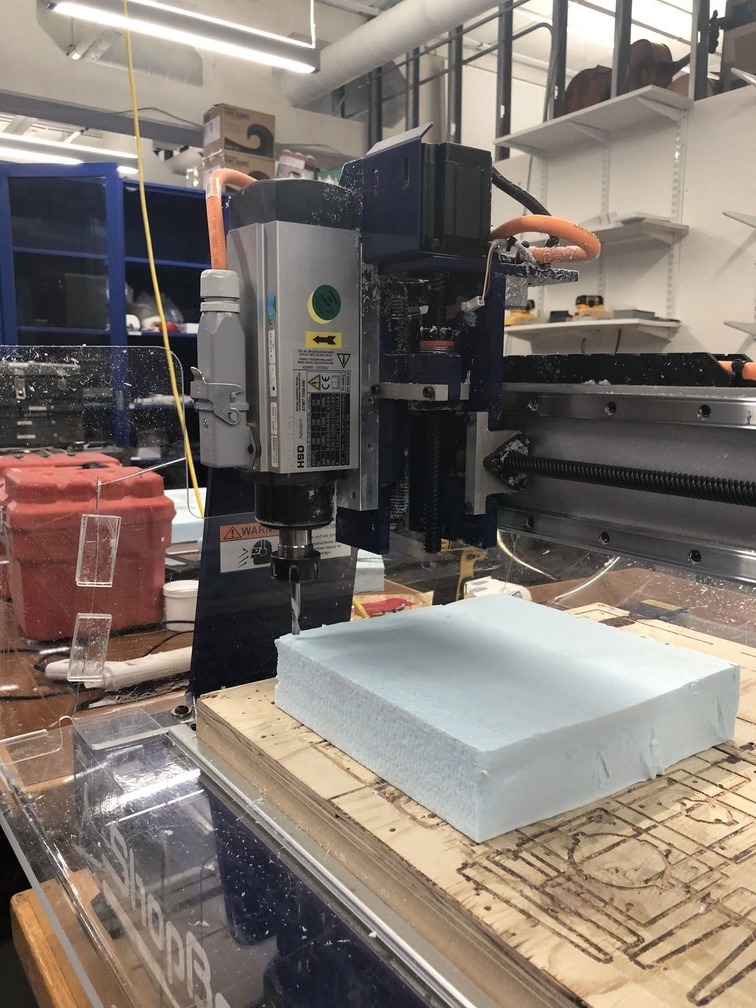

Although I have used shopbot for many times, this was actually my first time running the machine by myself. I did a "roughing" cut and a "finishing" cut.

Finished Milling!

Produce a fiber composite

Matarial I needed to make the composite:

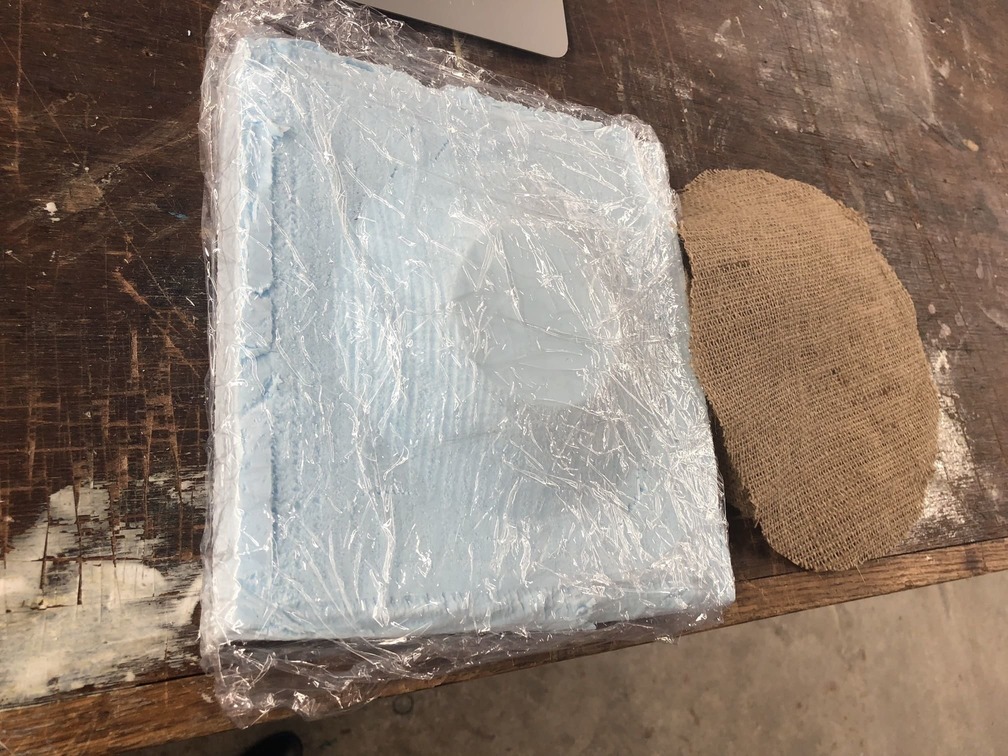

Put Plastic sheet on the mold that acts as the plee ply.

I applied epoxy to two layers of burlap. I wasn't sure about how much epoxy I should have applied, so I put as much epoxy as it all soaked. Then I put another plastic sheet as peel ply on burlap. However, I forget to put cotton to absorb excess epoxy.

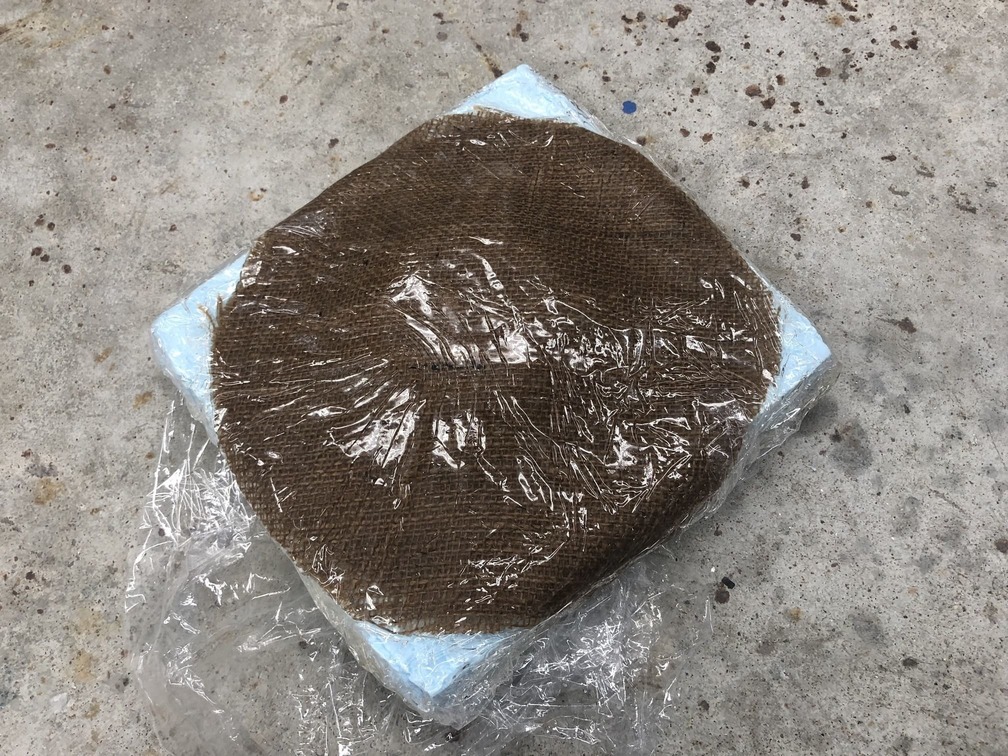

I put the mold with peel ply to a vaccum bag, then vacuumed it.

Burlap Composites Plate

12 hours later, I checked the bag and it was very hard and fully cured.

Here is my plate! Although I didn't use contton to absorb extra spoxy, it turned out to be not too bad. Since I used two layers of burlap, my plate is actually very rigid.

I am using it as my fruit plate now!