5. Computer-Controlled Machining

- Design Challenge: Make something BIG!

- Software: Fusion360 | V-Carve

- Machinery: Shopbot

- Materal: Oriented Strand Board (OSB)

- Date Completed: 10.16.17

Brain Storming & Testing

I was thinking of building a convertible table for my apartment, since my kitchen is too small to even fit a table. I came up with multiple ideas of folding a wood, which works perfectly when I did the laser cut using cardboard. I brought the design to the shop and want to see whether the OSB can bend or not.

- Top left: After generating toolpath, Shopbot is cutting my testing bending piece.

- Top right: Ready to bend.

- Bottom left: I am bending the board slowly to see how much it can go.

- Bottom right: It broke after bending over 90 degree.

Design

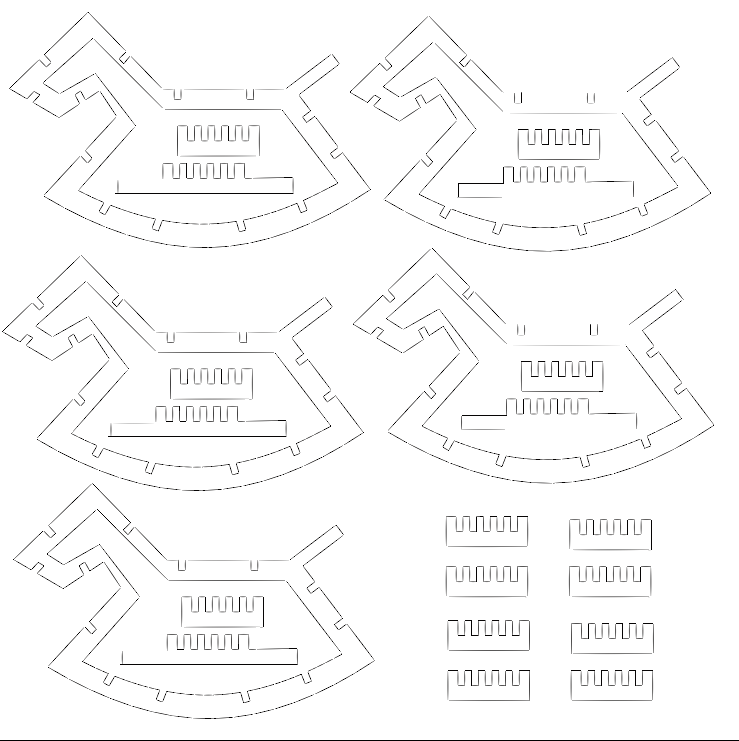

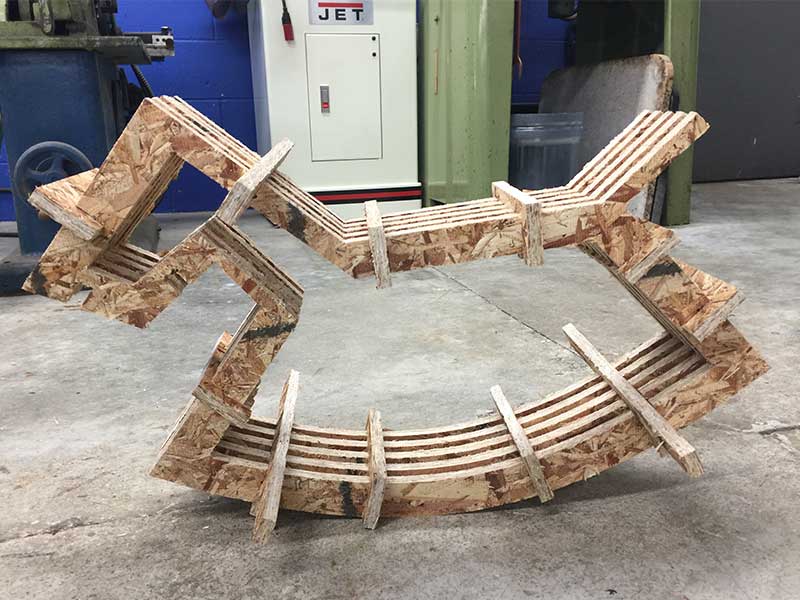

I decided not to make a folderable table due to the limitation of OSB. Then, I came up this idea of making a ROCKING HORSE for my nephew when I saw this. I used Fusion360 to draw the horse and then used illustrator to arrange the best way to cut.

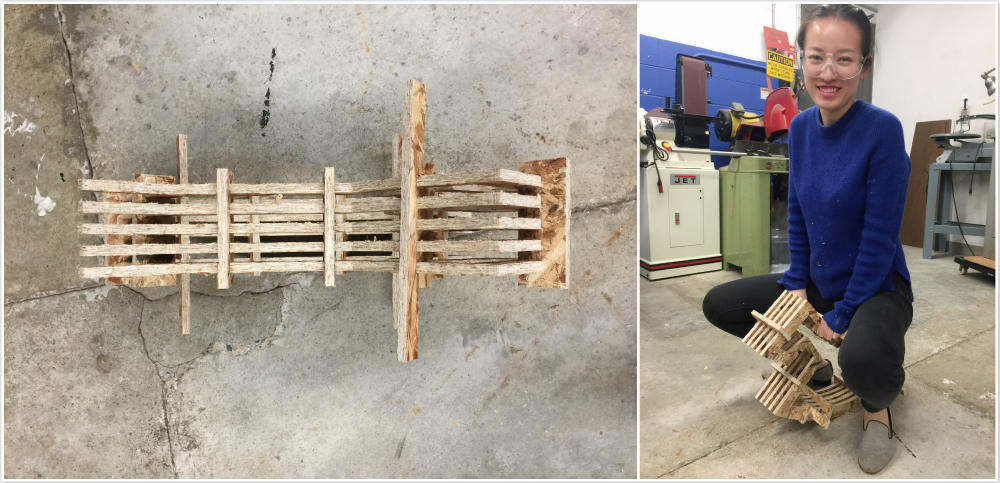

Kerf Testing

I need to know the percise width of the kerf that I should use before cutting the actual piece. I hope I can assemble my rocking horse without any glue.

- Top left: I ended up pick 0.43 inches for my kerf and cutting the outside.

- Top right: Auto-zeroing Z axis.

- Bottom left: Be very CAREFUL when adjust the origin. Avoid screw! We should design everything within 47*47 inches avoiding cuting the screw on the coner of the board.

- Bottom right: I have tried with different witdthes and toolpathes( cutting outside or inside).

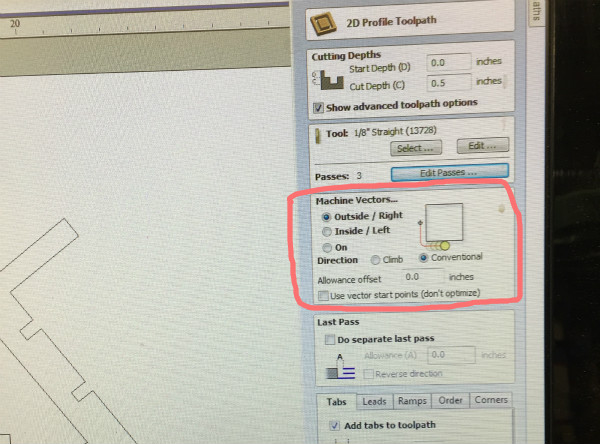

Test Cutting & Issues with kerf

I have 5 pieces OSB for horse's body, but I decided to cut only one first and see how it fits with the assembling piece. I am really glad that I did this, because not all the Slots cutting out in the same size. I looked the toolpath carefully and found out that some of the slots were cutting inside and some were outside. Both Daniel and me could not figure out what went wrong.

I decided to generate two toolpath with some cutting outside and the rest cutting inside.

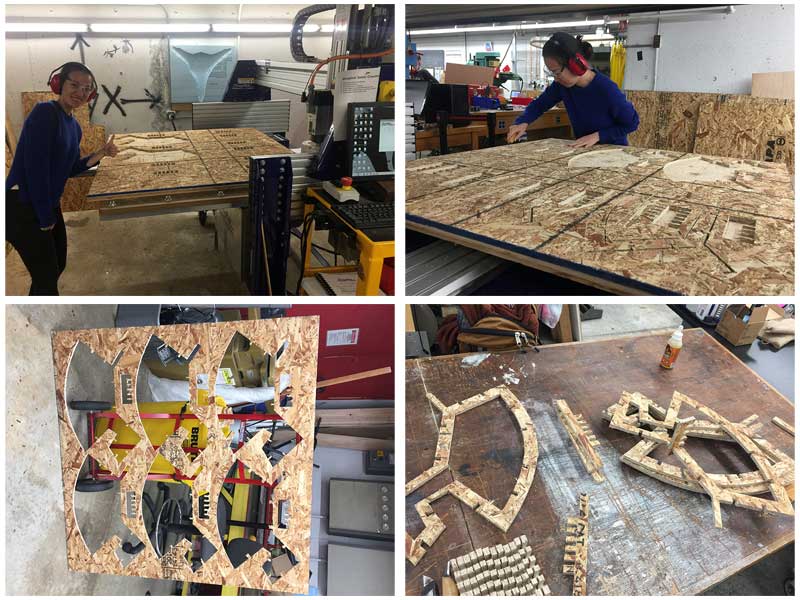

Finally, it is ready to cut!

- Top left: It took about 50 minutes to cut.

- Top right: I was cutting tabs.

- Bottom left: I think I did a good job arranging the space!

- Bottom right: Ready to build!

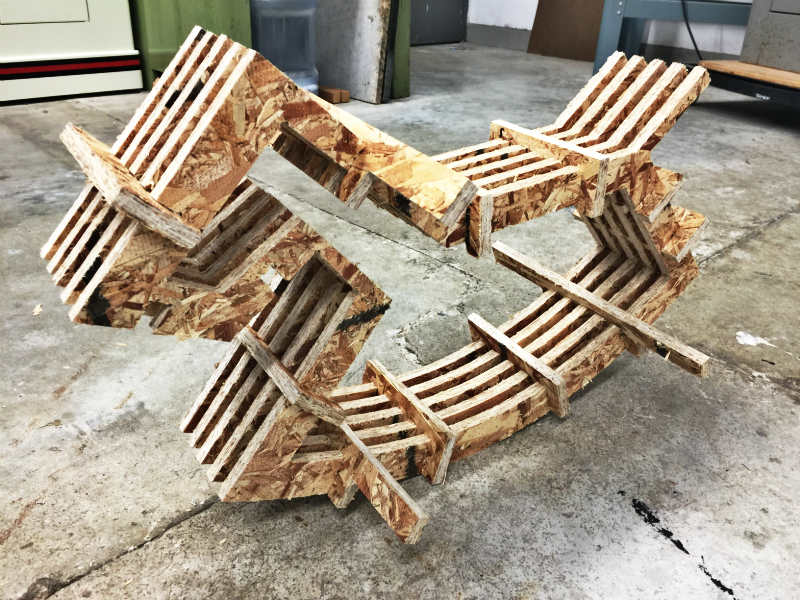

Surprisingly! All the pieces fits together perfectly. And it seems pretty strong!