Make Something Big

Guitar stand

Onsrud CNC Machine

We started out by measuring the OSB in the wood shop, which has a nominal thickness of 1/2" and, theoretically, an actual thickness of 15/32" or

.46875". In reality, we measured a thickness of .4455". We also ran through a speedy Mastercam tutorial by Zain.

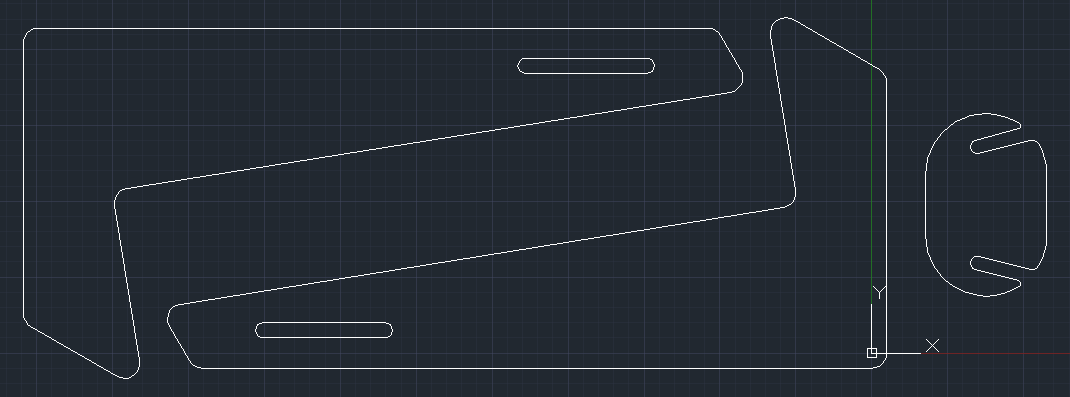

For my "make something big" project, I wanted to make a stand for my guitar in hopes that if it were on display, I would play more often. I found a stand online that I liked, and drew it up in AutoCAD (Figure 6a). Some dimension considerations:

- The good people of the internet suggested a 9 degree angle would create the optimal lean.

- The slots on each leg are 1/2" wide to easily slide the center wedge through.

- For the angled slots on the wedge, I had to make sure I had a steep enough angle so that the tops of the legs wouldn't intersect prematurely. This ended up being 15 degrees from vertical based on the placement of the slots.

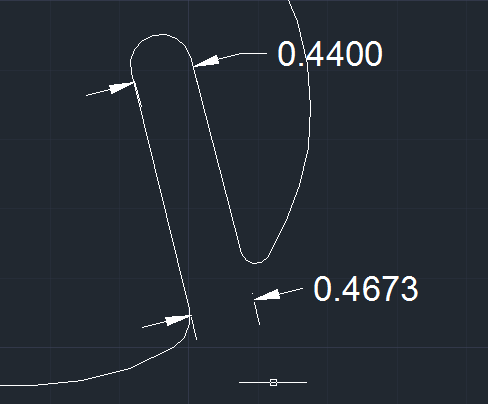

- I decided to try a wedge joint of sorts by starting the mouth of the slot at .47" and then tapering it down to .44" (Figure 6b).

When we brought our drawings to the shop, I was advised to make the outer "wings" of my wedge a bit chunkier (at least 1" wide) so they didn't completely fall apart under any sort of pressure. We used Zain's Mastercam template, which made things pretty straightforward. Once the pieces were cut, we sanded and filed off the edges, and it was ready to go (Figure 6c).

Total time: 5h

×

![]()

Figure 6a

×

![]()

Figure 6b

×

![]()

Figure 6c