how to (almost) make (almost) anything

3D scanning & printing

working linkage from a single 3D print

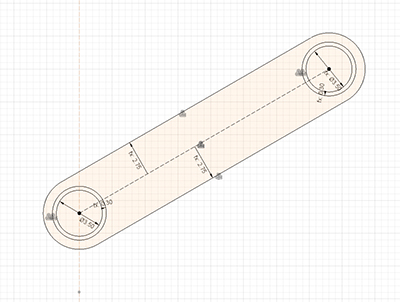

I remodeled the Jansen Linkage from a prior week using Fusion 360 and considered the tolerances of the 3D printer. I parametricized the relationships between parts in the model so that if and when errors occured, it was easy to revise the model.

parametricized arm with minimum clearance for 3D printing

parametricized arm with minimum clearance for 3D printing

Test prints had shown that the Sindoh 3D printer could clear 0.3mm yielding seperate parts that could move indepenedently from one another. I built the model around this figure in an effort to make the smallest working linkage that I could.

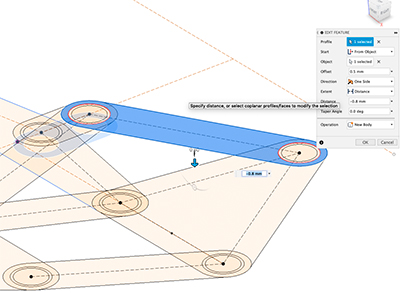

Whereas in preparation of lasercutting I had designed the assembly in two dimensions, I exhaustively modeled the linkage in three dimensions for the purposes of this assignment. I found the workflow in Fusion 360 to be intelligent as one models in a two-dimensional sketch environment first and then can extrude pieces into independent three-dimensional objects. This is particularly useful in this case because the components have alignments that are most evident in a sketch environment but need to be maintained in the three-dimensional model.

extruding an arm from the initial sketch

extruding an arm from the initial sketch

The extrude function also handles offset positioning; this feature enabled the flat sketch to become a complex 3D model while maintaing clearances and alignments and helping you avoid collisions or self-intersection (although there is no automatic self-intersection detection that I found, it does help keep the model organized and thus easier to inspect).

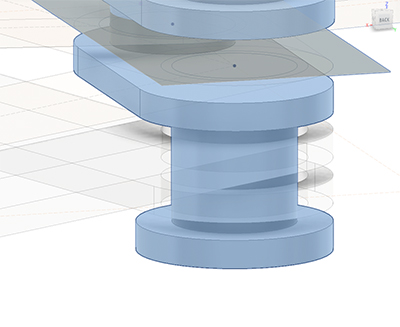

detail of the central crank

detail of the central crank

Further edits to individual objects (called components in Fusion 360) are made by selecting them and working on them directly. Again, the workflow is intelligent and allows for the extrusion of objects relative to other components in the model; this enabled precise tolerances and clearances to be maintained. As stated above, I used 0.3mm for the free clearance between components and I used 0.5mm offsets in the axis perpendicular to plane of rotation; I was more generous with clearance in this dimension because of the increased surface area between components.

revised linkage design for 3D printing

I exported the completed 3D model as a .stl / binary file and imported the mesh into 3DWOX Desktop to set up supports, infill density and pattern, and layer height. I changed layer height to 0.10mm for a more detailed print and left other default settings. Scrubbing through the preview confirmed that the piece would be printed as desired.

using the layer viewer in 3DWOX DesktopAfter the 3D print completed, I removed it from the bed and inspected it. Several of the components were sticking together despite my attempts otherwise, and I used tweezers and a knife to remove as much support as possible and separate components that had been fused together during printing. I broke the central crank during this process, but was able to salvage the rest of the model. a mostly working miniature linkage

Fortunately, I had parametricized every significant variable in the design and could go back and easily reconfigure the model. But it was easier to simply scale the model up by 100% and reprint using the ABS printer with disolvable supports. I scaled the mesh and uploaded the new .stl file to the shop server and the print was waiting for me the next day. Swish.

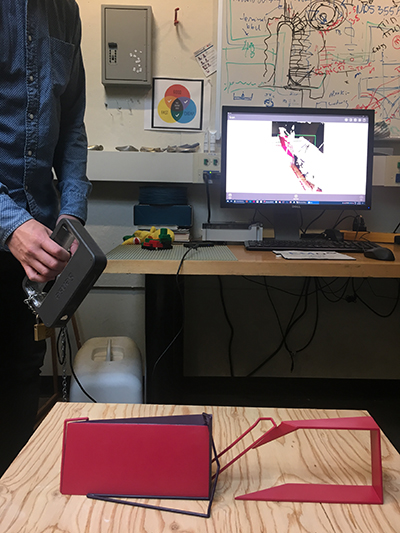

scanning | Sense

let's put this 3D print back into the computer

let's put this 3D print back into the computer

The experience scanning was best summarized by an excerpt of magnetic doggerel stuck to a machine in the architecture shop:

fiddleing in worship

never bare together

but sweet music

That is to say it was tragi/comically tempermental and I was unable to achieve a cogent representation of the sculpture I attempted to scan. I tried plain backgrounds, irregular backgrounds, standing close and far, orienting the scanner in landscape and portrait and moving the model or moving myself. As I ran out of time and was beginning to make a scene, I retired from this project for the time being and will return with another method.

nope.

nope.