Molding and Casting

Molding and Casting the Beast (2E) Logo

Design and Toolpath Creation

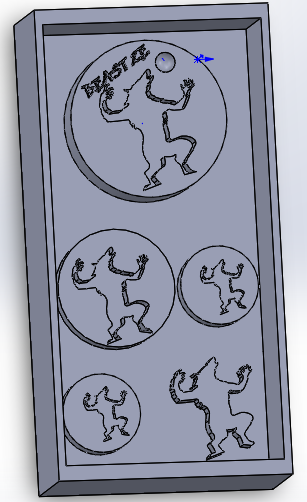

For this week's assignment I decided I would make something that I could gift to my secret Sarah, so I decided to make molds that I could cast using chocolate, melted gummy bears, etc. I first started off with the SVG of the logo and later imported it into Solidowrks and came up with the following design:

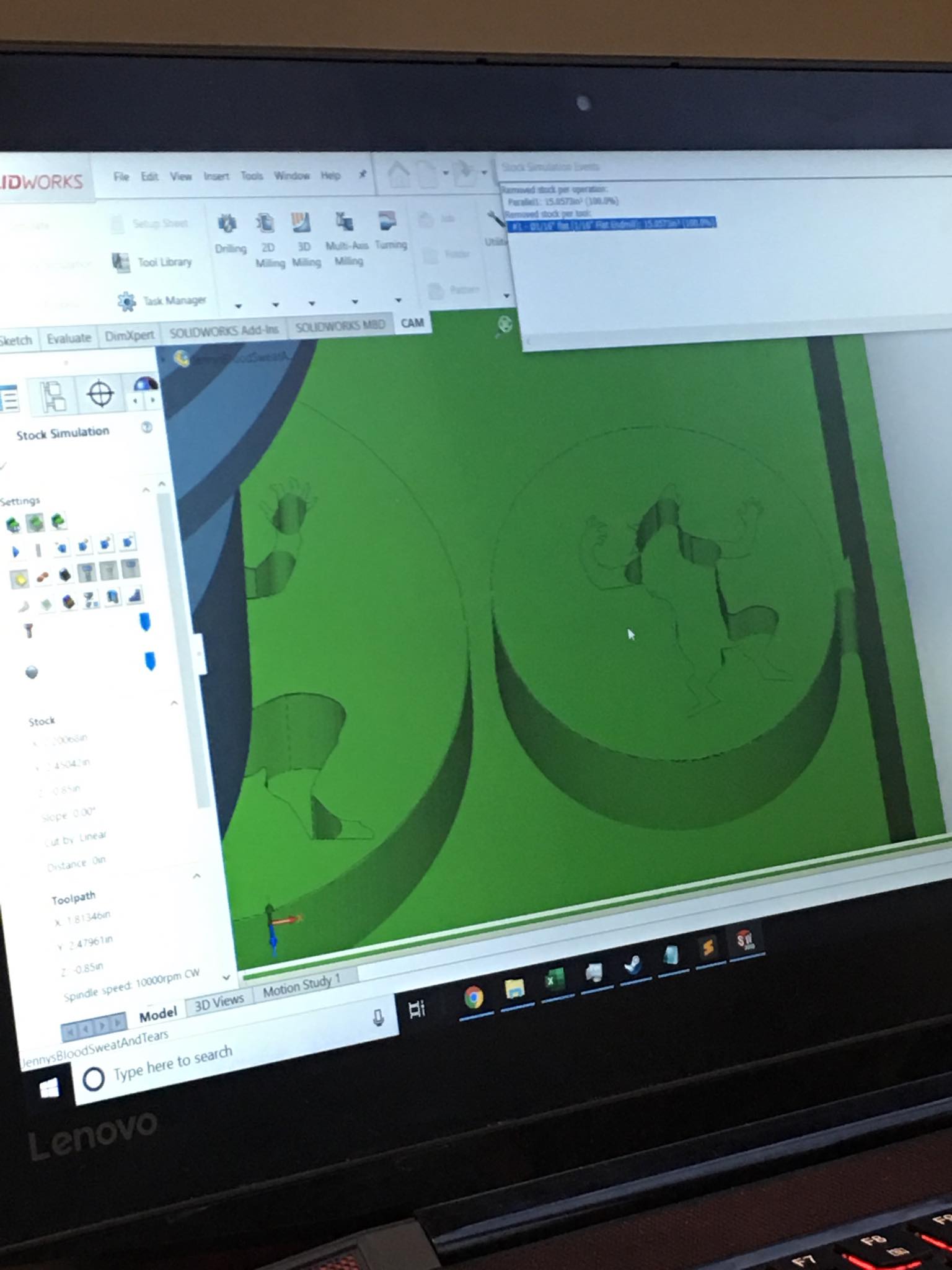

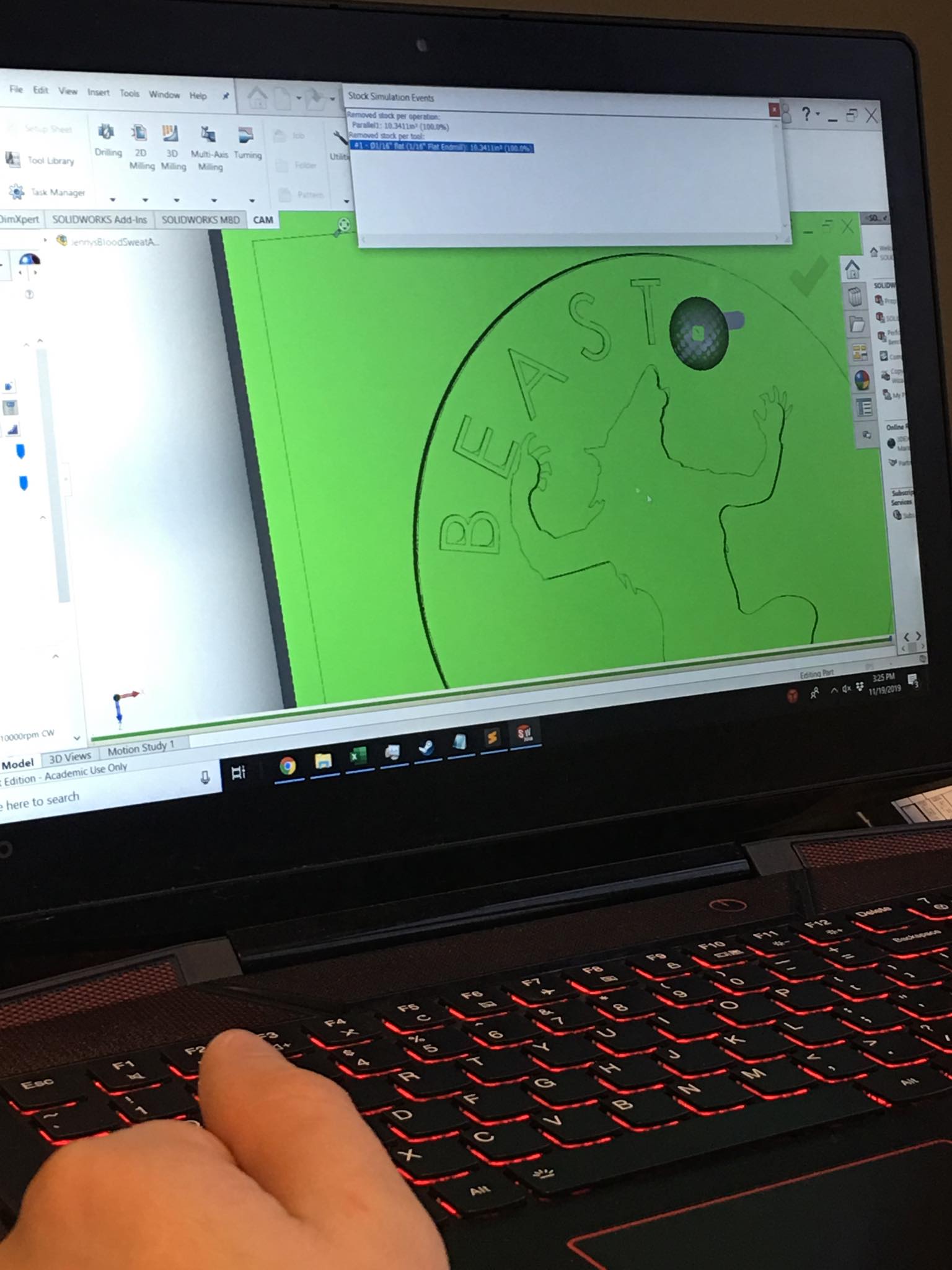

I was able to use a smaller tool as I was one of the last people in line for the Shark. Despite using the smaller tool, some of my features were too small to be completely milled. They were still cute though, so I kept them that way. I did change the font in the design to make it millable however. For the toolpaths we (Anthony) created 3 separate ones using Solidworks CAM. These were adaptive cutting, contouring, and parallel.

Milling the Wax Block

These different toolpaths took 30 minutes, 1 hour, and 45 minutes repectively. Adaptive cutting was with the 1/4" tool while the rest utilized the 1/16" tool. Between contouring and parallel cutting I manually removed some of the wax to minimize the risk of the tool being broken by plunging in too deep. The milling succeeded as expected from the toolpath.

Creating the Mold

In order to create the mold, I used the method of filling the wax with water to find the volume. I split it up evenly and mixed two even parts of oomoo 25 to pour into the mold and let it set for 2 hours. After 2 hours, the mold turned out very nice.

Casting with Various Materials!

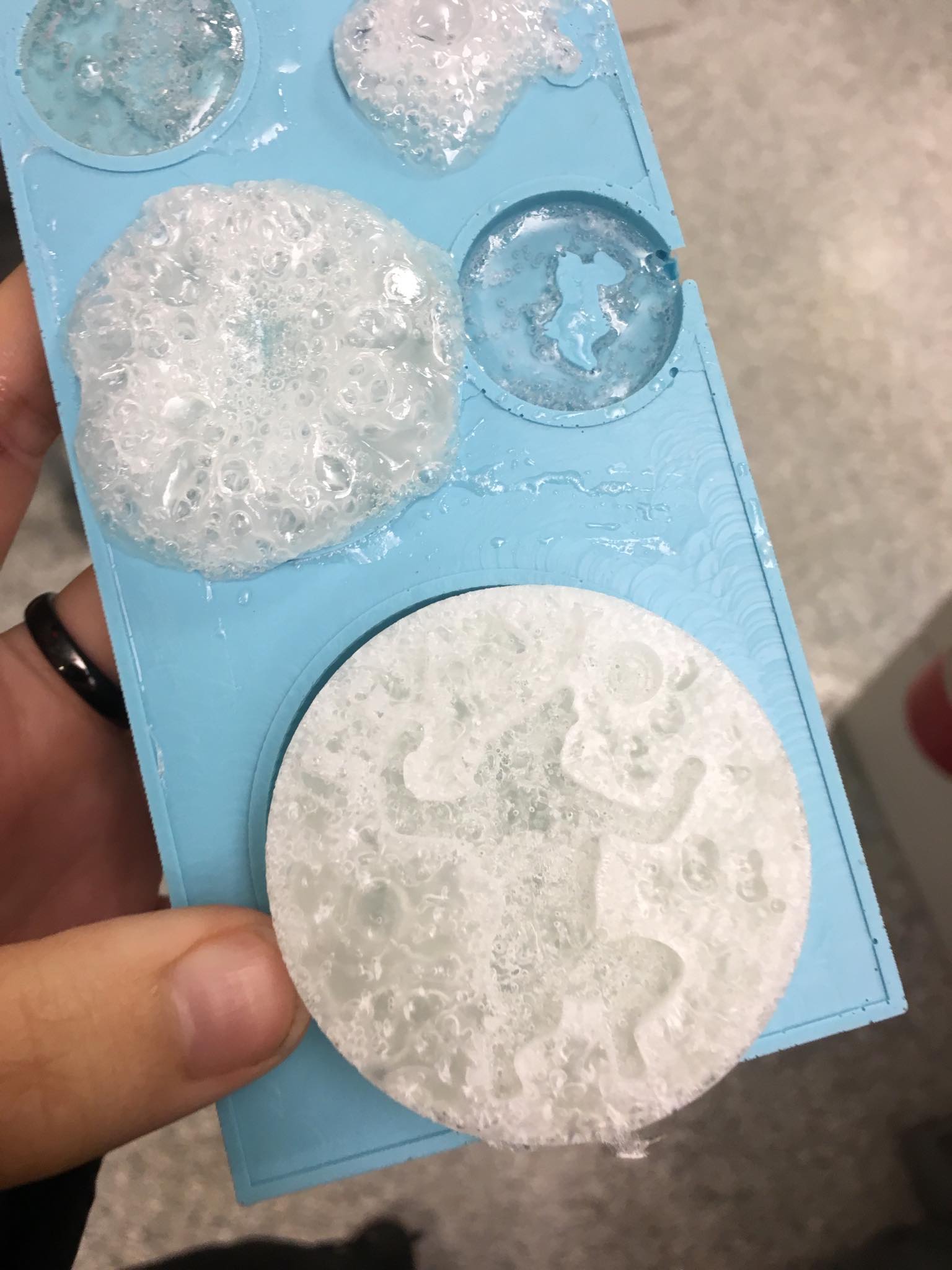

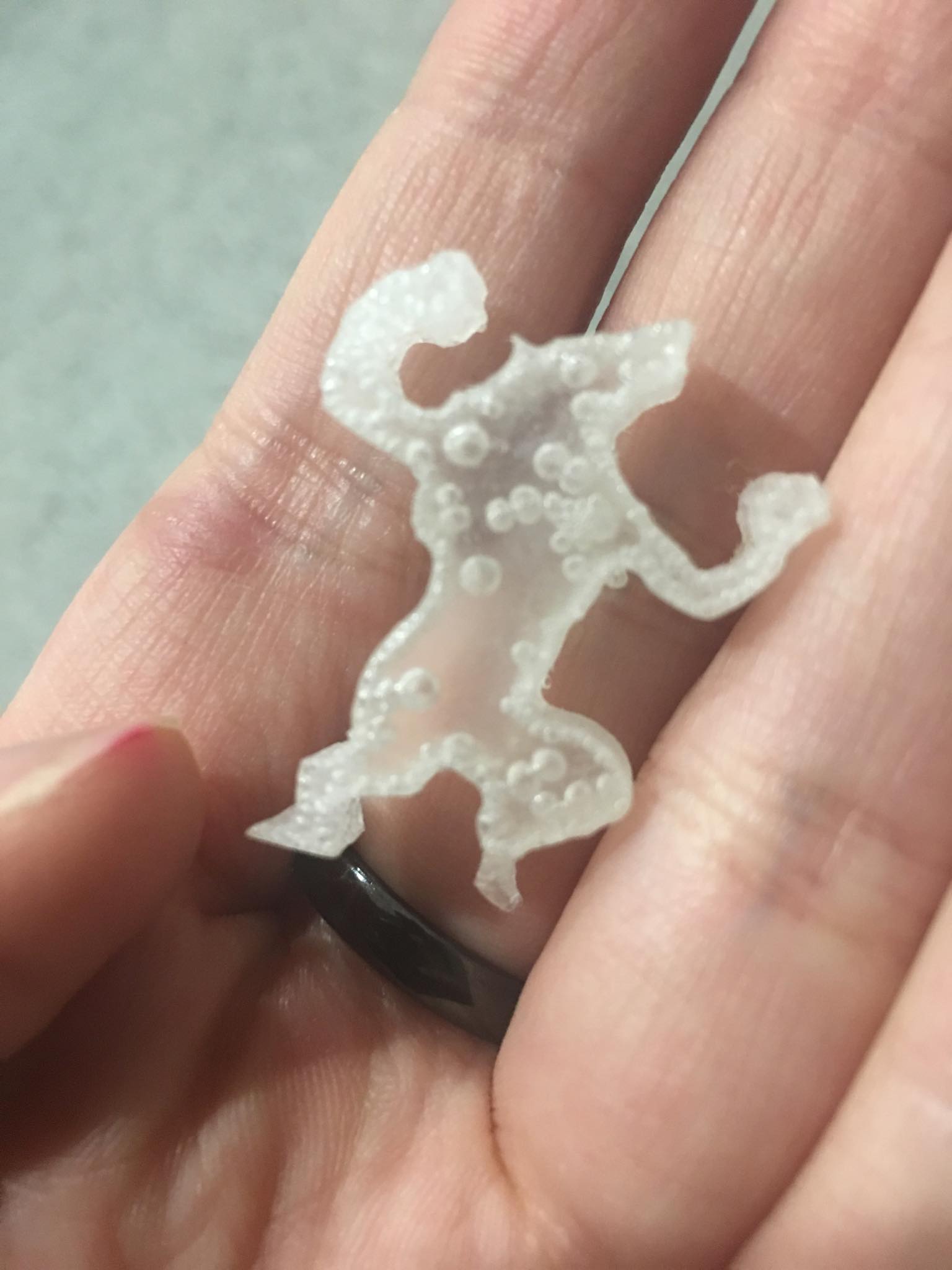

I first tried casting with plastic. I mixed two parts of smoothcase 326 (clear version) and poured the mixture into the mold. I let it sit for 45 minutes and it bubbled up because I poured in too much at once and it had an exothermic reaction. I tried recasting with the same clear version, but this time pouring slower and placing the mold into a vaccuum to reduce the number of air bubbles. The case ended up coming out better, but I was unable to completely get rid of the air bubbles (see the two pictures for a side by side comparison) and I also tried adding in color to one of the molds to make it yellow!

I then attempted to cast some candy by melting down chocolate and gummy bears. The gummy bears were poured and cooled and turned out alright. You could kind of see the definition in the mold but it wasn't able to harden completely. The chocolate on the other hand was very brittle and the smaller pieces broke when I attempted to take them out, but the definition was very sharp on the casts that succeeded.