Wildcard Week

Sheet Metal Design

Group Project

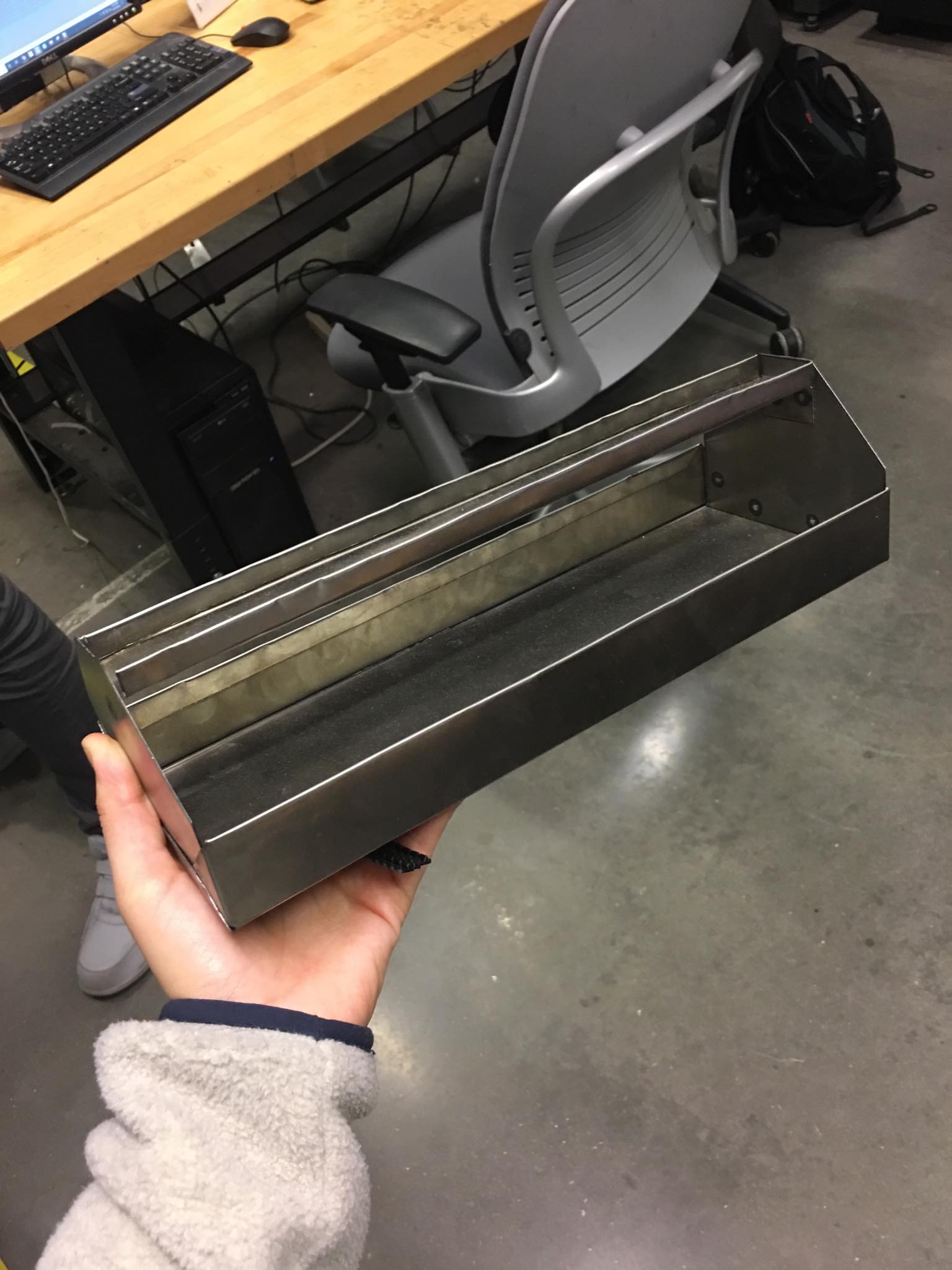

As an introduction to folding, welding, and laser cutting sheet metal the group made a tool box.

Initial Design

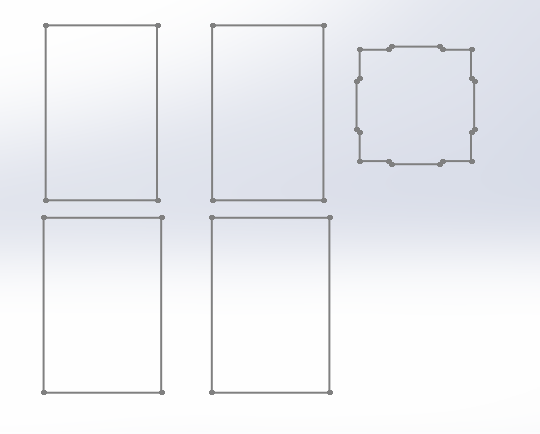

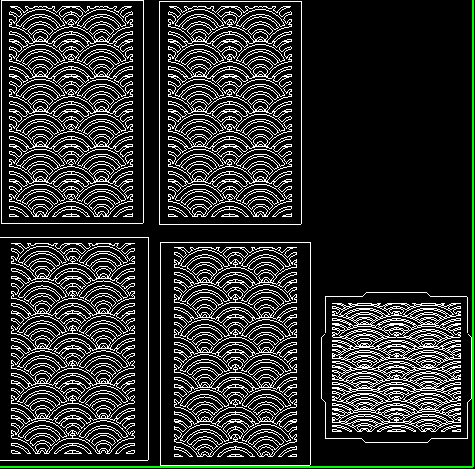

For this week I decided I wanted to make a lantern with a pretty design. I created the following design in solidworks and overlaid an svg over it in Inkscape. At first my design was too dense and I had to decrease the density before it wouldn't crash the program. Then I needed to draw extra lines to ensure that it was cutting out in the right space. Due to time constraints I reduced the design to only being on one side of the box. From then I exported my file to the software generated a toolpath and attempted to laser cut it out.

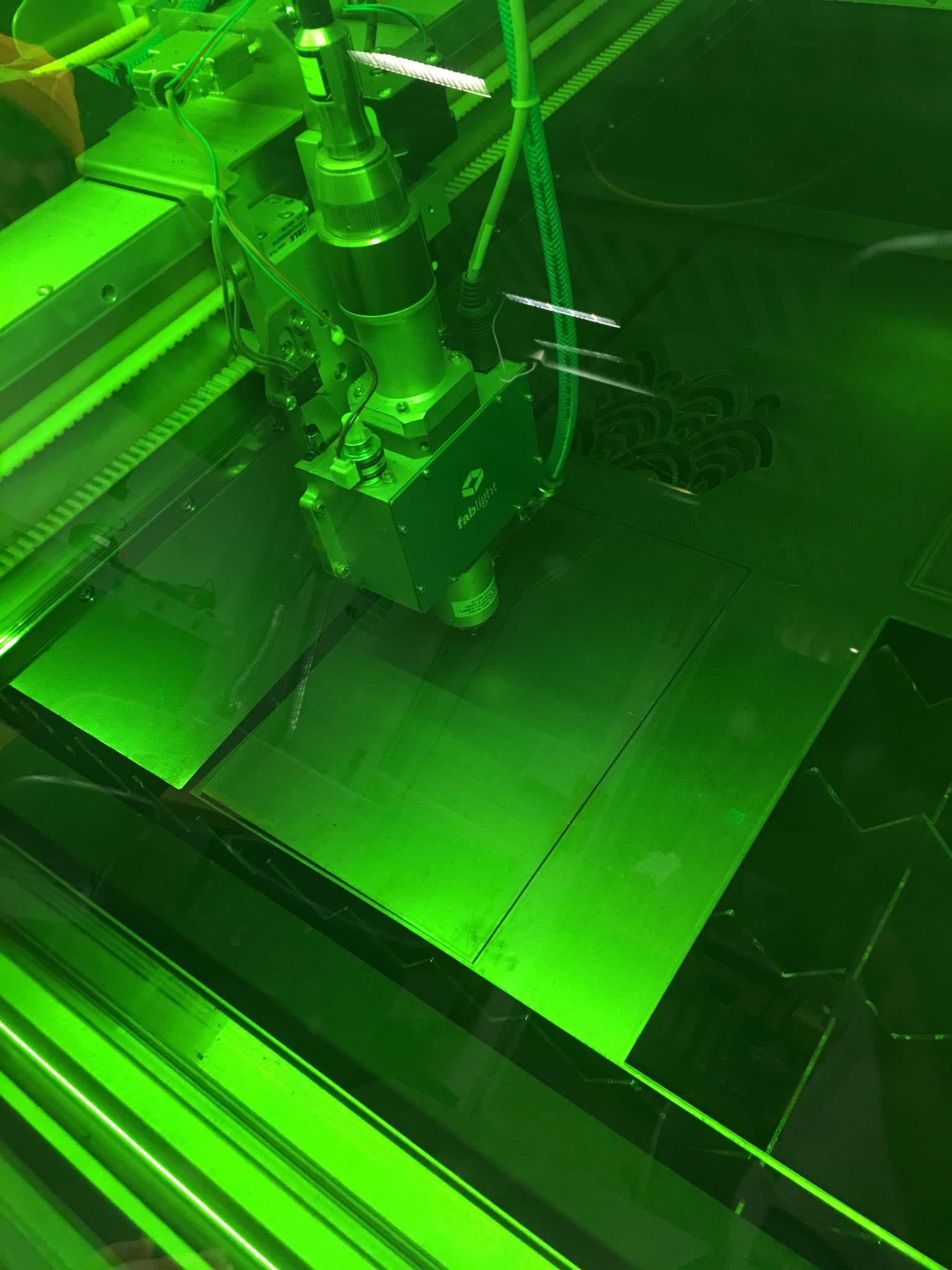

Laser Cutting

Unfortunately, when it came time to laser cut the design it did pretty well up until the laser begain cutting where it wasn't supposed to. Tom and I were both confused about why it wasn't cutting correctly. The toolpath generated didn't indicate that it would go and cut in these areas. Sadly, it did tear through the nice design that I had prepared. Because time was running low, I ended up opting to go for a smaller design and overlaid that design and laser cut it instead. This time it cut without any major issue.

Assembly

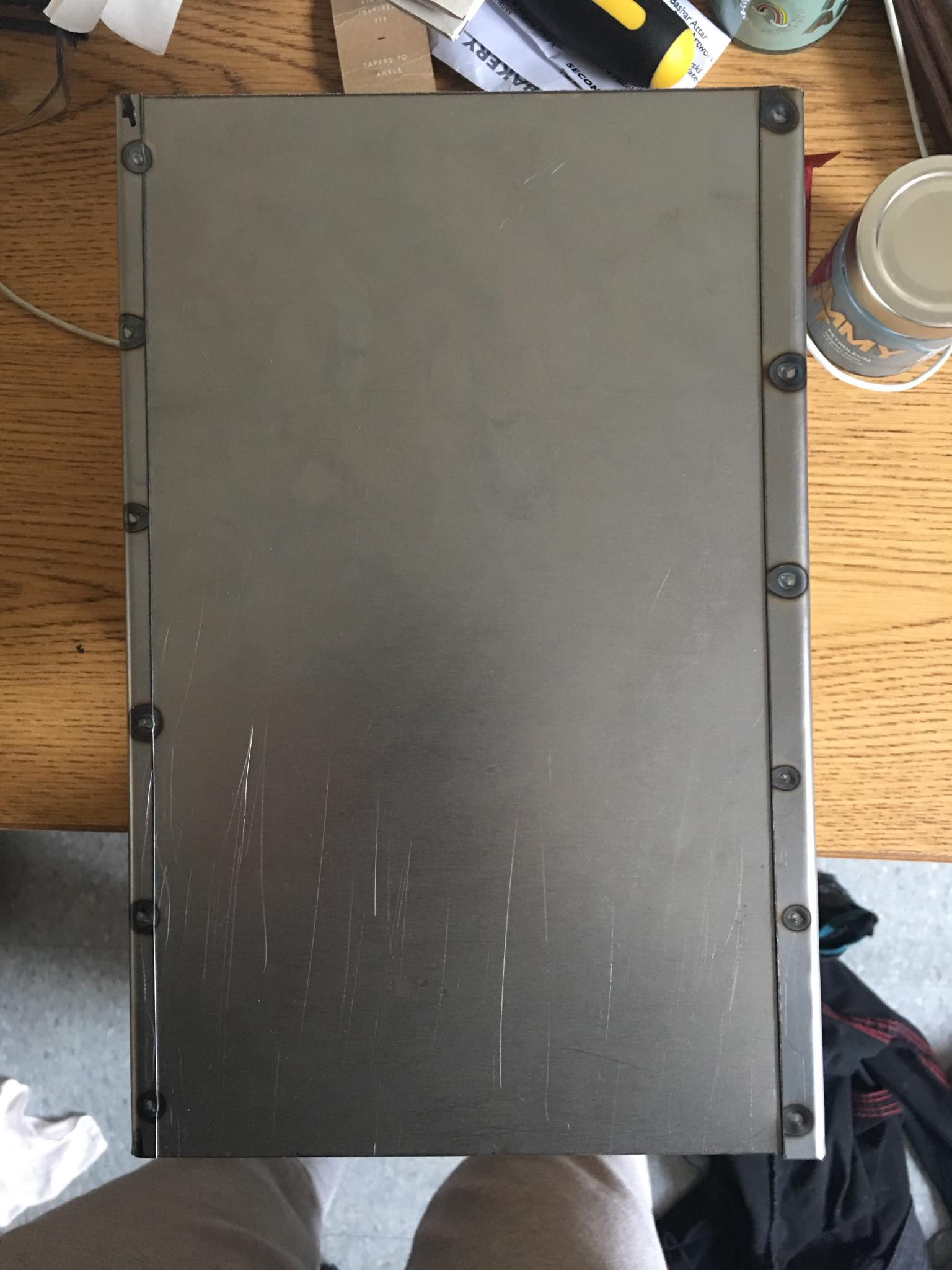

I first filed down the rough edges from laser cutting. I had originally designed my lantern such that two panels were wider than the others by a cm, which would result in folding tabs that were half a cm wide on two of them. I bent both of the panels as well as the top and I then proceeded to spot weld the panels together. My spot welding abilities drastically increase as I figure my way around the machine. Due to the size of the lantern I wasn't able to spot weld the top and instead just fit it in.