Assignment:

- Group assignment: characterization of lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

- Design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

- Cut something on the vinylcuttere

Tool Used:

- GCC laser cutter

- CorelDRAW

- Onshape

Laser cutter

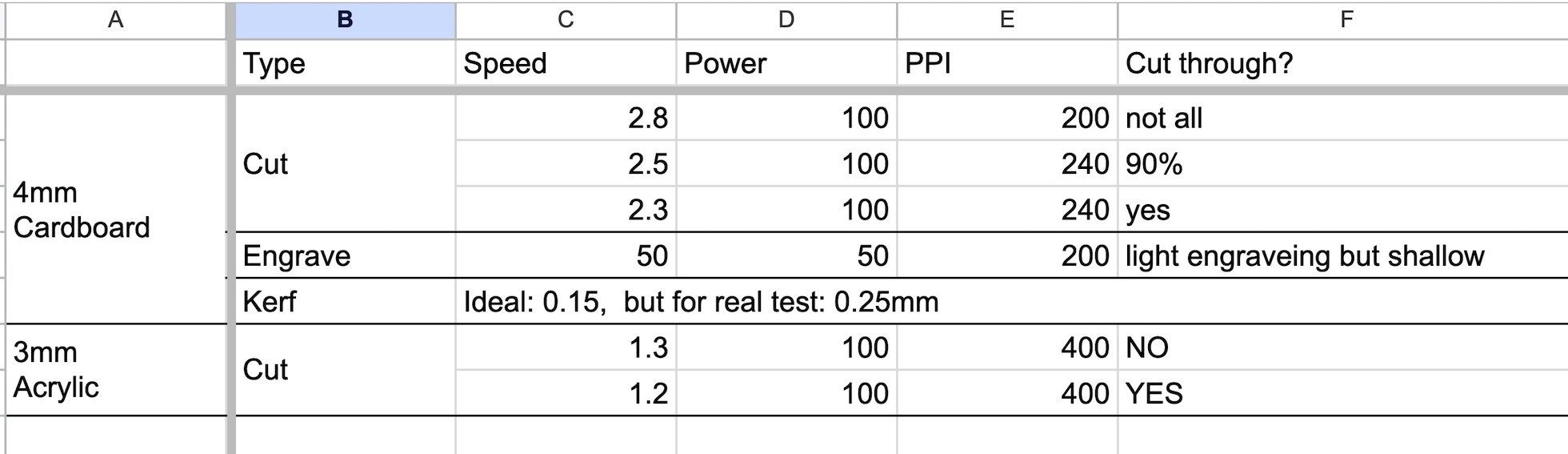

After failing couple times for the group projects, I have documented an excel sheet of characherization of llasercutter’s focus, power, speed, rate.

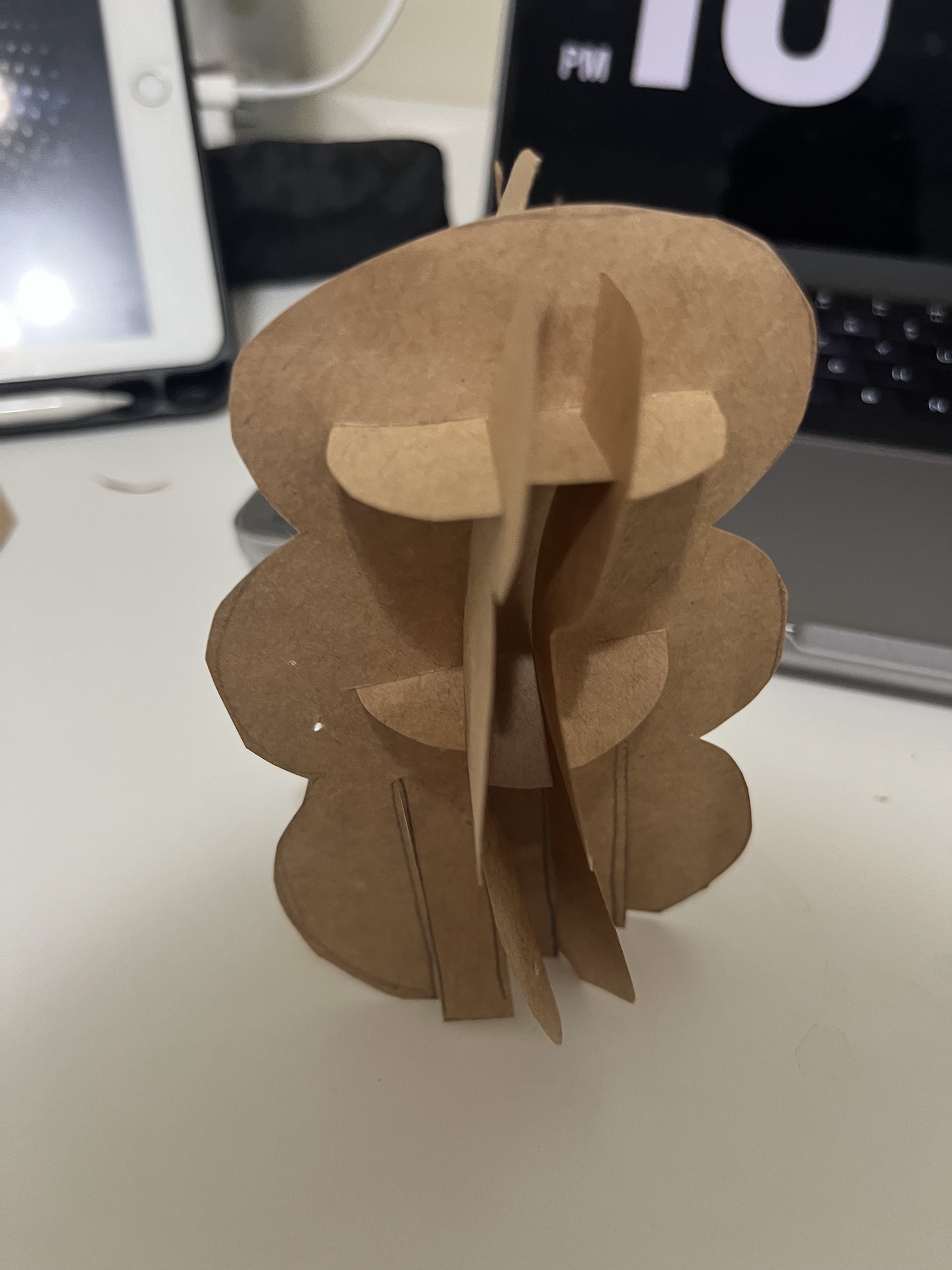

Version 0

For my individual assignment, I began with a quick prototype, labeled as “Version 0,” using paper to have a clearer understanding of the design, assembly process, and overall concept.

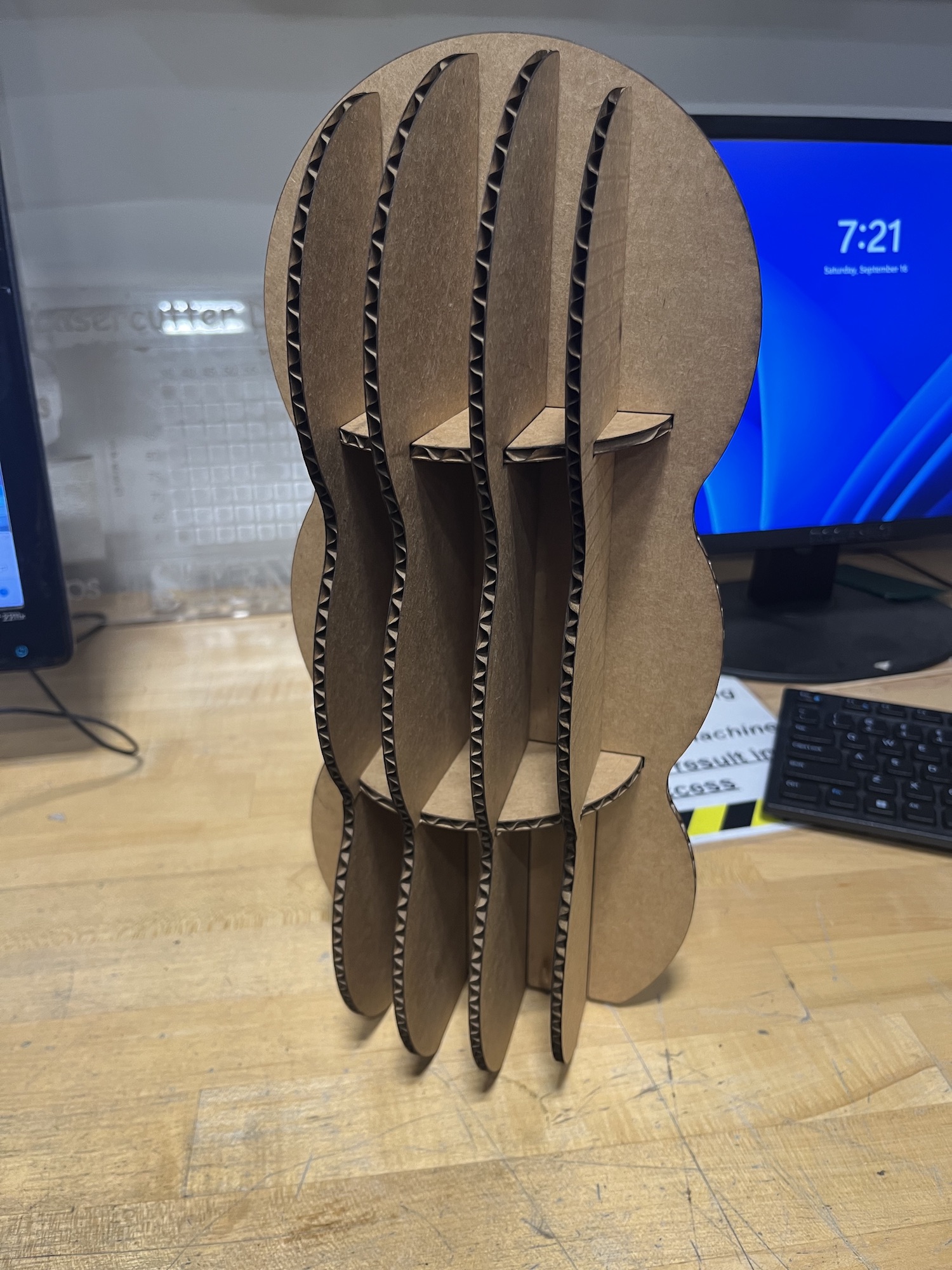

Version 1

Upon having the design, I transitioned to Onshape for the actual design work and crafted a scaled-down version to expedite the iteration process. However, reality often deviated from my expectations, and the first version(Fig-4) had several challenges:

- The thickness of the cardboard posed assembly difficulties compared to the paper, necessitating a redesign of the assembly method and sequence. So I have to redesign the CAD for the assembly method and sequence.

- Some edges is too thin, so it’s easily bended. Definetely not a good sign.

- I forgot to design a base for fixing it.

Version 2

Then I start to modify my CAD desgin, mainly changing assembly method to the center piece. After cutting out the version 2, it went well. I have proven the new assembly method works.

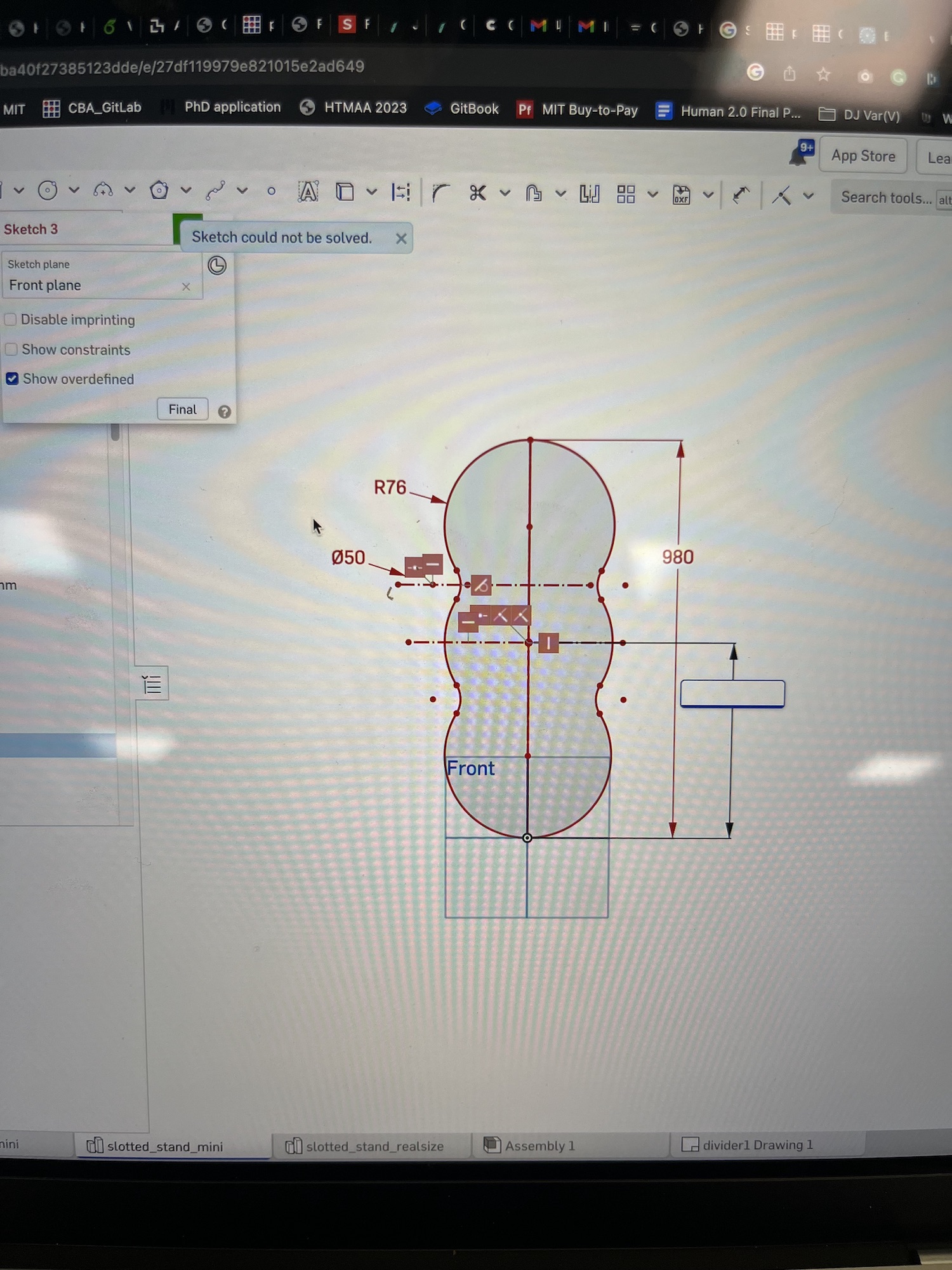

Version 3

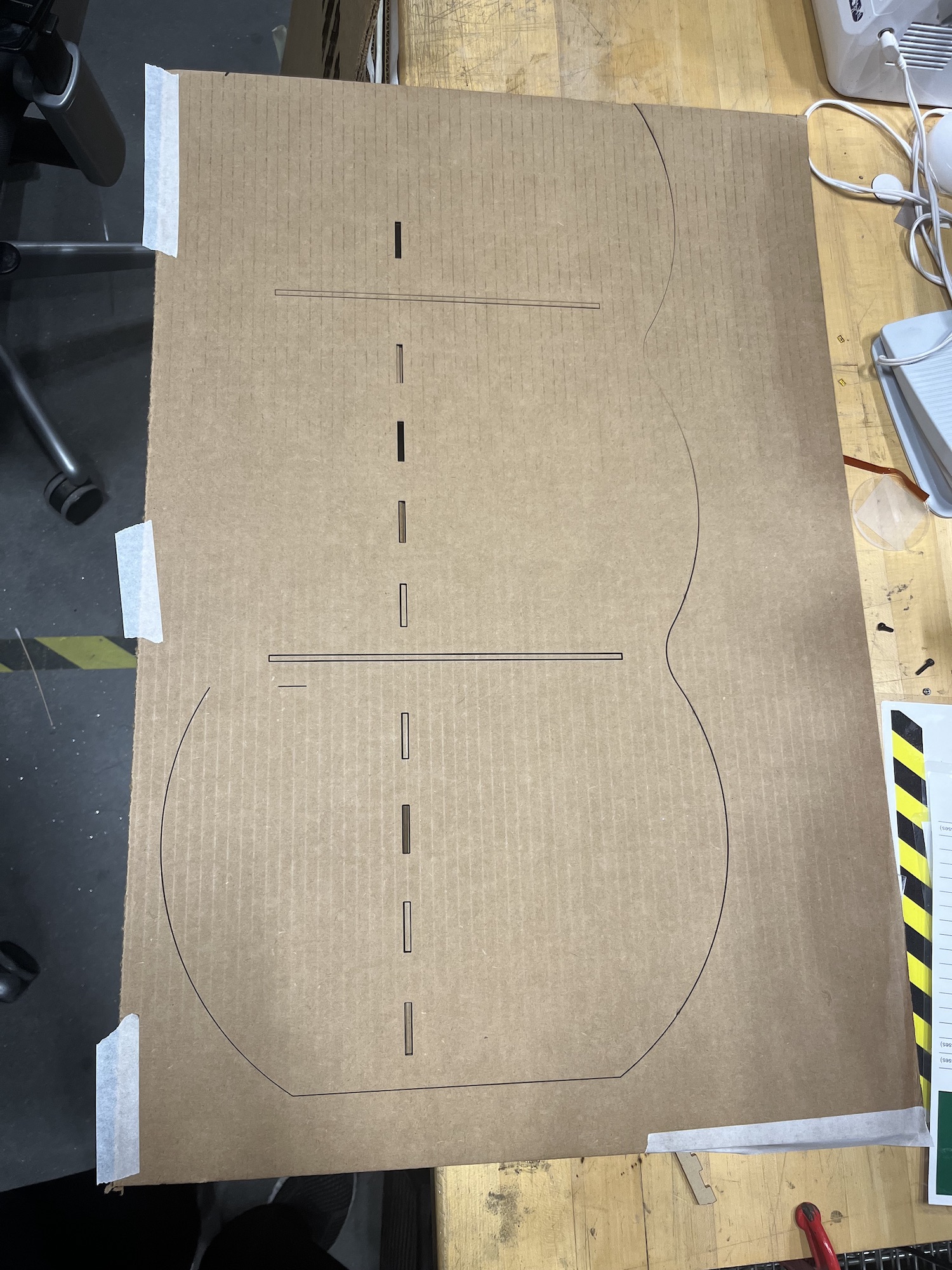

Having successful experience on last iteration, I decided to scale up the project to full size. However, several issues emerged, as some parameters in the CAD design were fixed and not adaptable(fig-6) to significant ratio changes. To address this, I adjusted parameter ratios between certain elements to rectify the issue.

I then proceeded to finalize the design and carry out the cutting. Managing the real-size bookcase is hard to handle, I change the height of the bookcase twice to fit in the lasecutter’s bed size and the size of cardboard(fig-7). I wasted some cardboard because of it.

In the end, the realsize bookcase works smoothly. I placed a book inside(Fig-8), it’s stabile and functional. In Fig-1, I have arranged all the iterations side by side for reference.

Version 1 to Version 3

Vinyl Cutter

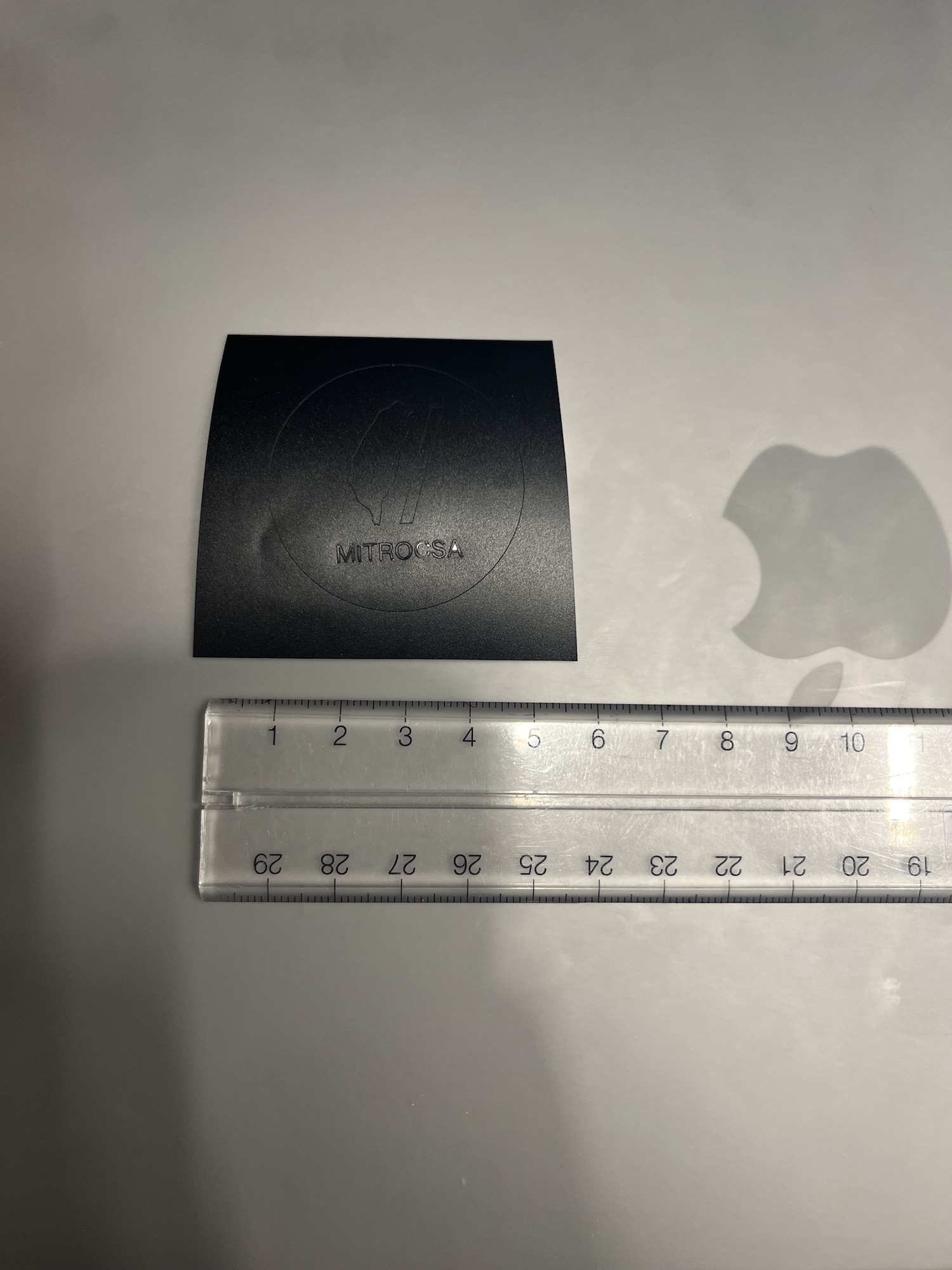

I designed a logo for Taiwanese Student Association few weeks ago, and never have chance to put an order on customed sticker services. So I thought this might be a good chance to practice and save some money to make the use of this class!

The size of my cutting is too small, therefore some detail are hard to weed. Maybe make it larger or redesign of it could have better result!

Additionally, I cut out a logo sticker of a soccer team for my labmate.