[04] 3D Scanning and Printing

Summary

The basics of 3D Printing and Scaning. We print an object that is only possible to create by an additive process.

3d Printing

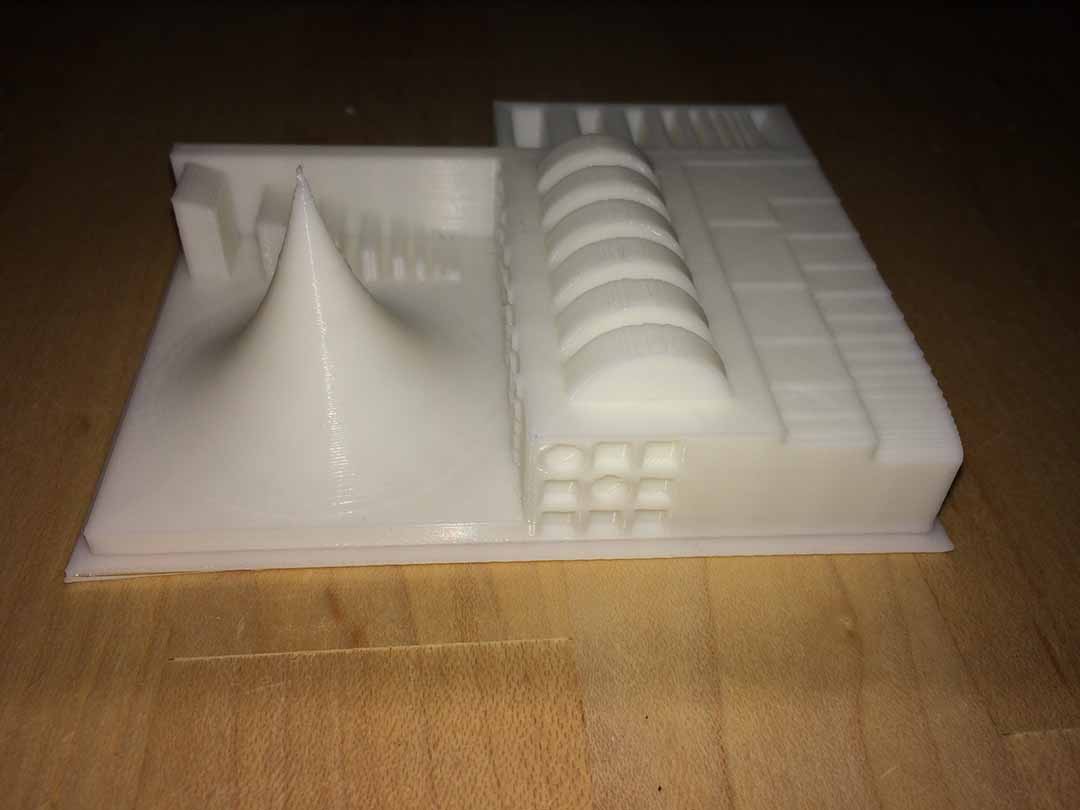

Although the way a 3D printer operates is very complicated and get a correct 3D print could depend on a lot of factors (even the temperature of the room), basic 3D printing is supposed to be a straightforward task.

Like all of the other projects, I realized that one of the most important factors to correctly 3D print is to understand the workflow that must be followed. In this case, 3D printers normally read .gcode files and GCODE files can be created from STL, OBJ, 3DS and other 3d files.

Workflow

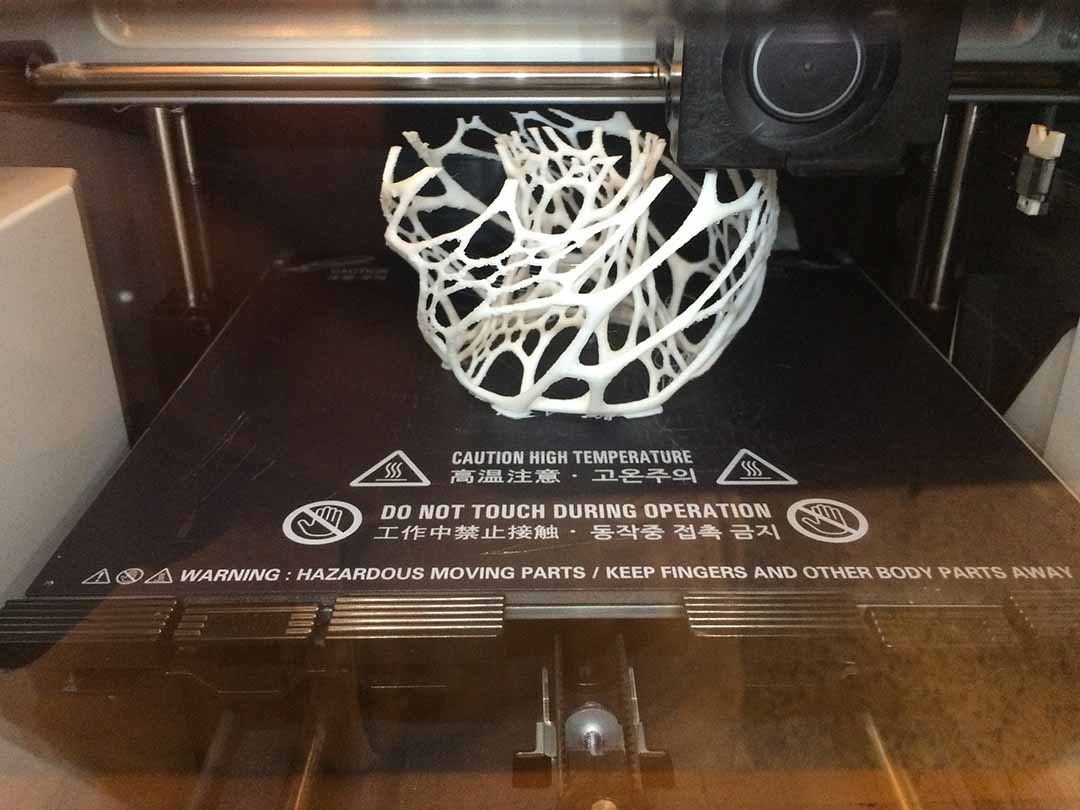

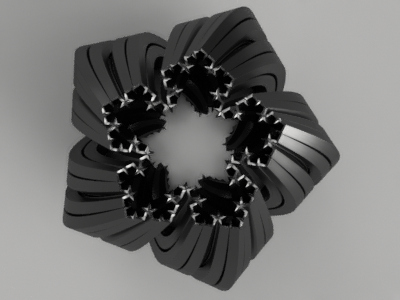

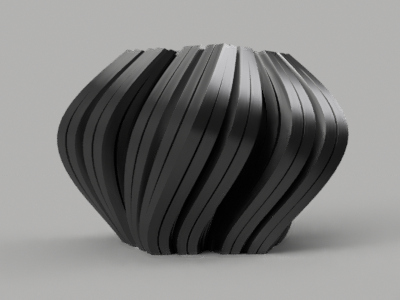

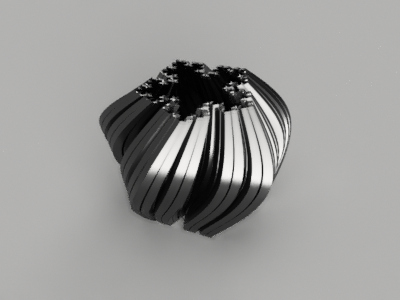

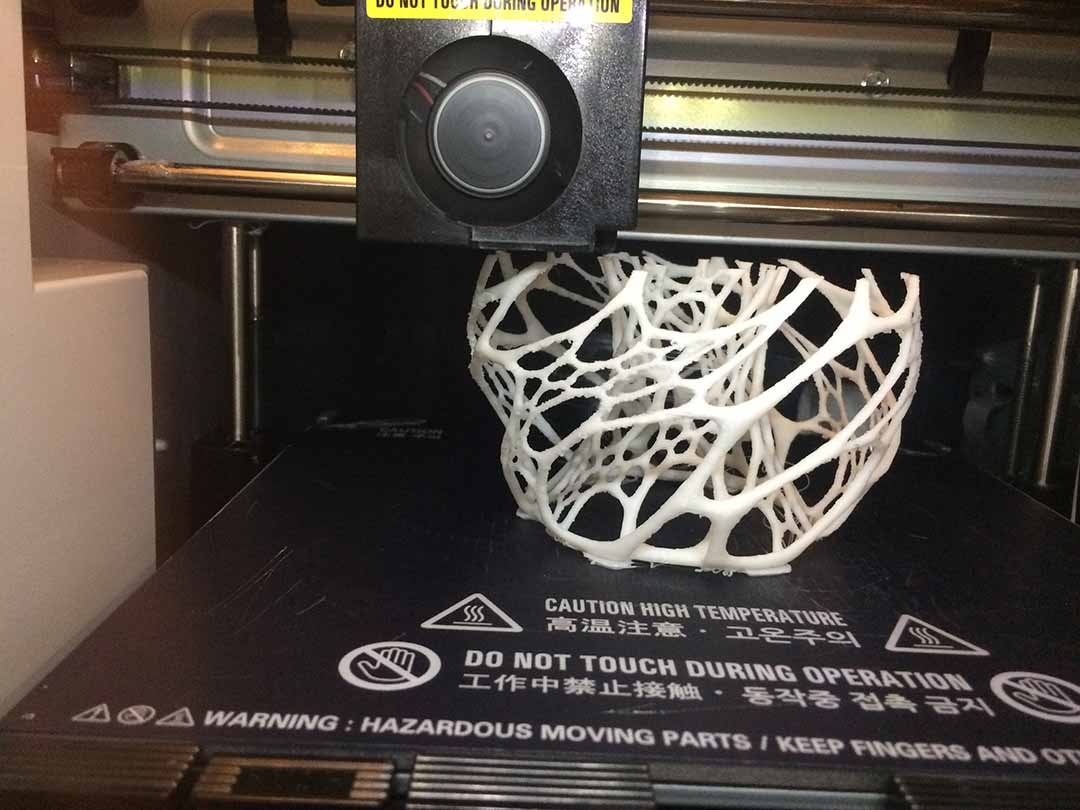

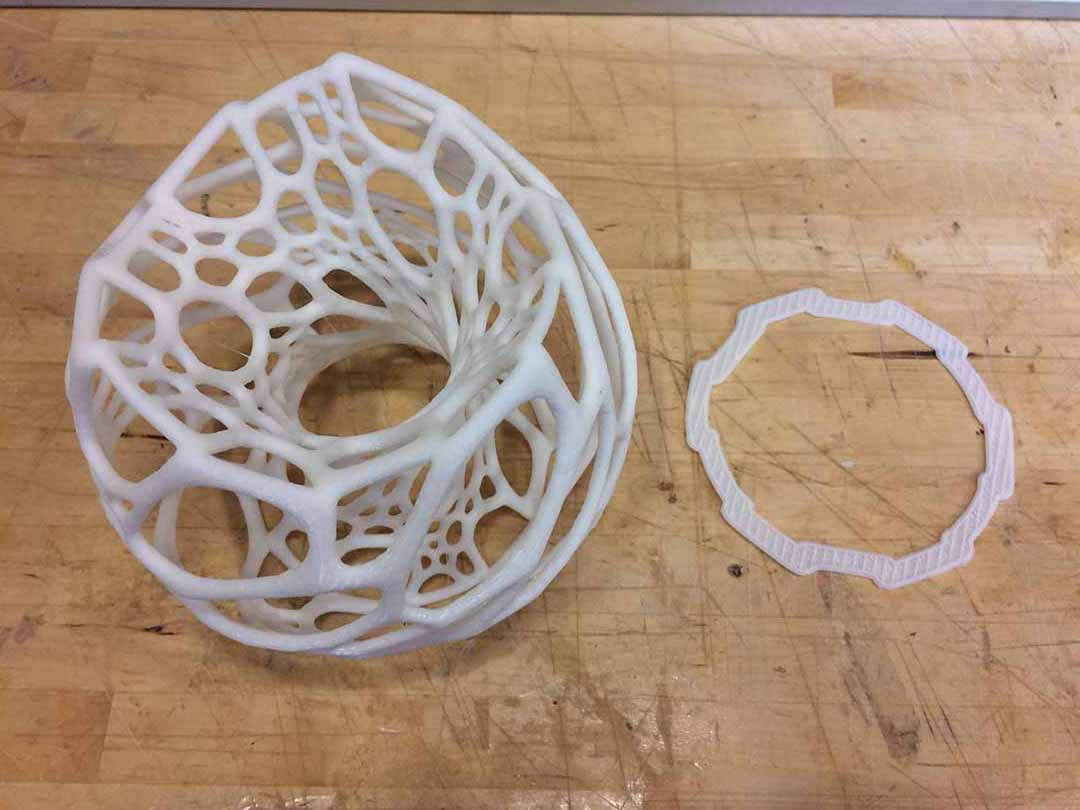

- Design a component: I used Fusion 360 to create an Fractal Vase. Since the Fractal vase crashed my computer, I downloaded a Voronoi lamp, a file that was much easier for my computer to handle.

- Save file as an STL file: Fusion 360 can create STL files (File > 3D Print). Thanks to this you can save your final design as a STL file.

- Create a GCODE file: Once you have the STL file you can use several software that allows you to create a GCODE from a STL file. I choose to use 3DWox Desktop since is the propietary solution for SINDOH 3D printers.

- Normally you will need a Rafts, Skirts or Brims. This will help you keep your design attached to the table while printing. You can learn more about this here.

- Some design need support, you need to be careful to take this into account. This could make your print to fail and you would have loose time on unsucesful prints.

- Print: Save the GCODE file to a USB. If your printer is not printing correctly, be sure to check this print quality troubleshooting guide.

- Post Processing: I used sand paper to eliminate the mistakes of the 3d printer.

This helped me to understand better how to use the software. I found that creating a fractal needs a lot of computing power. Although I managed to finish the design of the base, in the end, it was taking me 30 minutes to make a change in the design, and I did not manage to complete the design and close the vase since my computed kept crashing.

I also learned about Top-Downs design strategies. You can find a very interesting tutorial here.

Before printing is important to undertand that 3D prints need two things.

3D Scanning

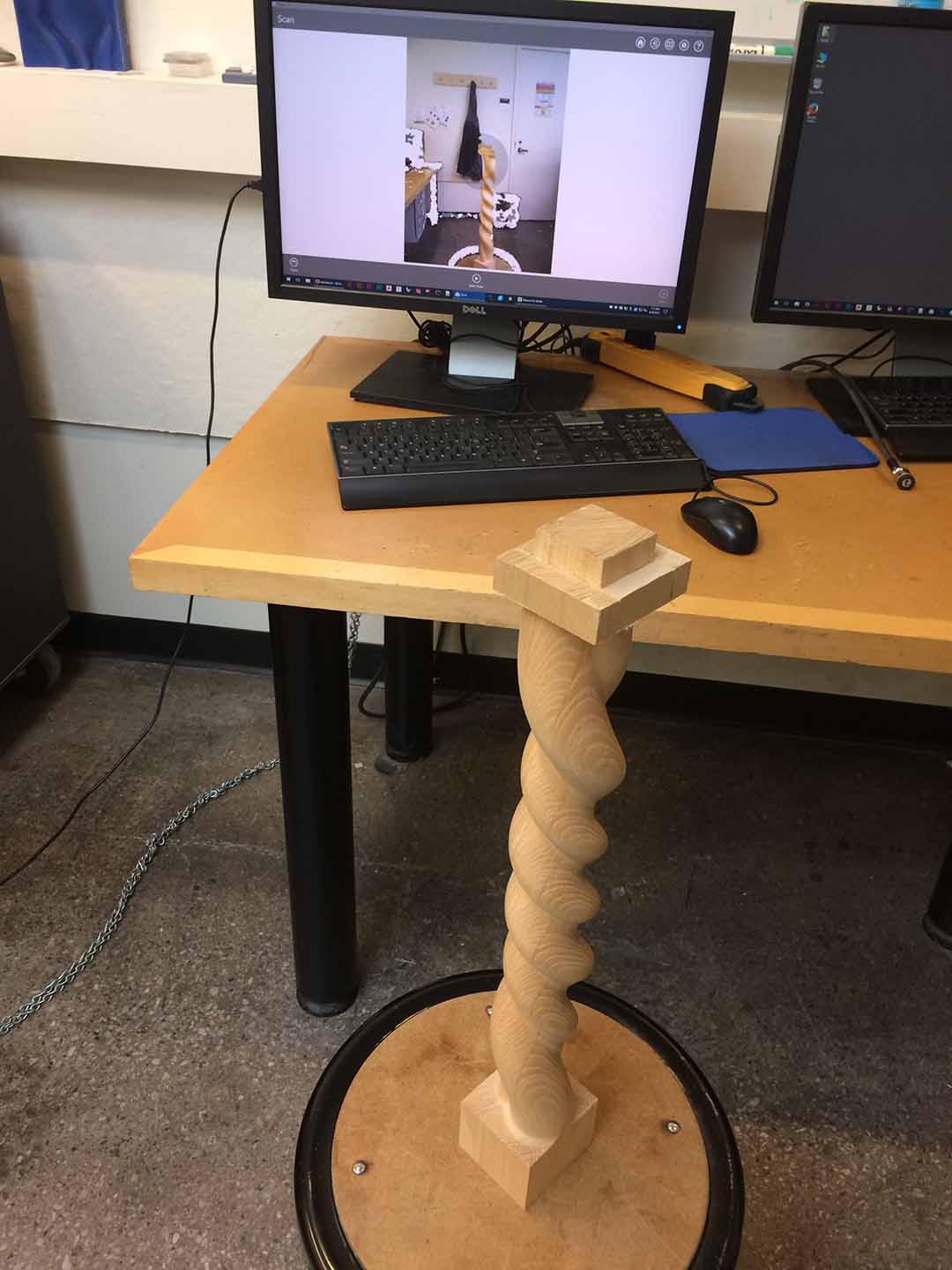

For the 3D Scanning we used Sense from 3D Systems which scans colors and form, up to 1mm of accuracy.

The process is very simple:

- Start by putting the object over a flat surface.

- Open the Sense App and select the type of object that you are scanning (small, medium and big objects, even persons).

- Move around the object until you complete scan it.

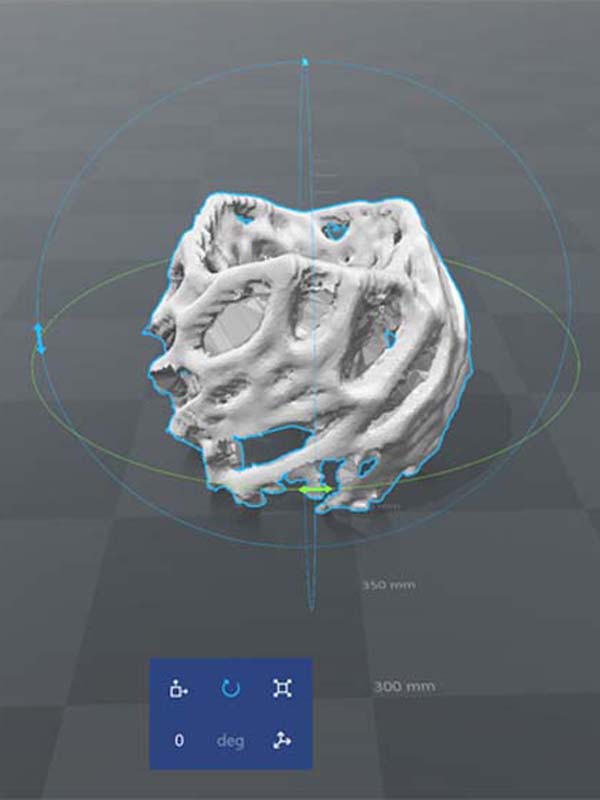

- Clean your scan and save your file as STL.

Scanning can be very tricky since the scan keep loosing track of the object. Also if the object is too small, scanning becomes a more challenging task. Keep in mind that the final model would not be exactly the model that you are scanning, but is a start if you do not want to model a very complicated object.