Week 12: Mechanical Machine DESIGN

A. GROUP DOCUMENTATION + IDEATION

A1. Group documentation

1.1 For this weeks assignment our section worked together to make a machine in one week! This was a HUGE effort and it was really cool to see everyone come together and spend many hours in shop to get our project done within the week.

1.2 We wrote up a full documentation of the process on Joao's page which goes into detail of every step of the process. For my documentation this week I will just go into detail on the components that I specifically worked on.

A2. Group ideation

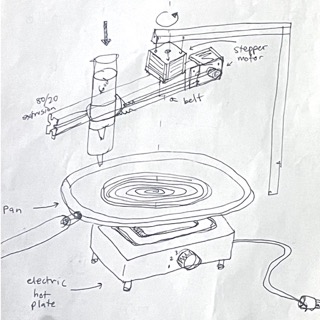

2.1 Our group had a few ideas when we first met, but after a few rounds of voting we narrowed it down to a circle drawing machine and a pancake printing machine. We combined these two ides and for our final machine made a pancake printer that uses radial coordinates rather than xy.

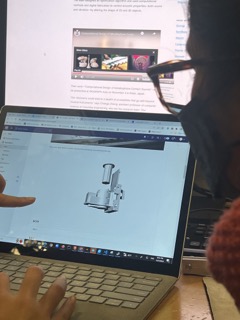

2.2 I helped specifically with the linear and radial arm design, specifically the 3D cad modeling, 3D printing, and assembly. We needed to design and fabricate components that would connect the multiple moving pieces together and it took a lot of group discussion and conceptualizing. Since most of the class is individual work it was really really nice to work with teammates to figure out a shared problem.

B. LINEAR + RADIAL ARM DESIGN

B1. Linear arm component

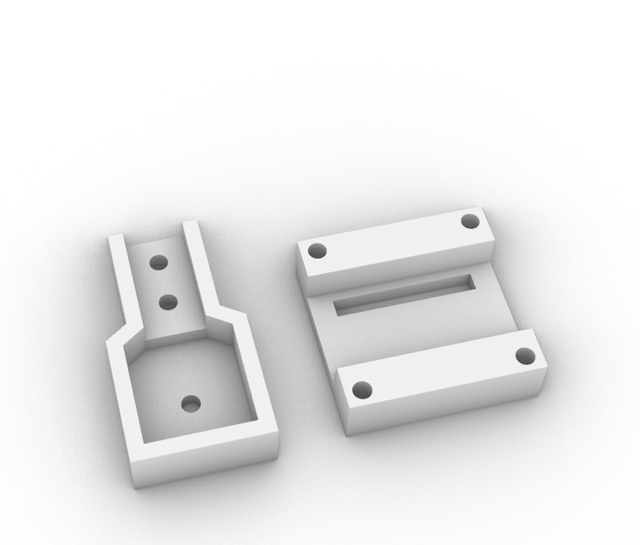

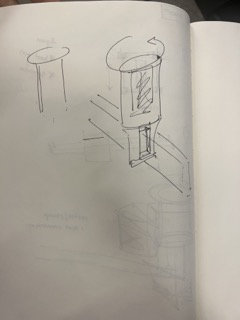

1.1 For the linear arm component we needed to print a few pieces. One that would connect to the scaffolding structure with a space for the belt to move through, and a space for the pancake batter tube to run through perpendicular to the linear arm. We also modeled a piece to hold the wheel at the end of our belt.

1.2 I worked with Alayah and Lakshmi on designing, modeling, and printing these pieces. We ran into a few issues while trying to assemble the arm after printing and found that we had to reprint some of the pieces. Specifically one of the parts that combined to create the arm attachment had to be reprinted with an extra slot so that we could tighten the belt once it was on our arm.

B2. Radial arm component

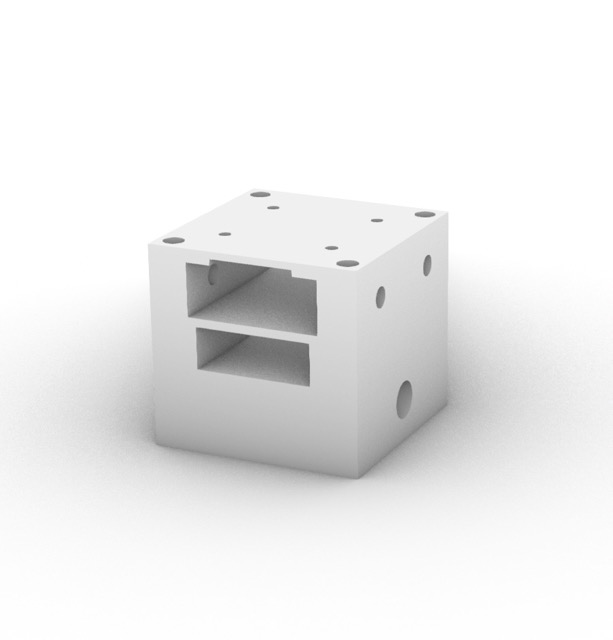

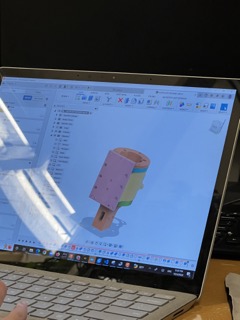

2.1 For the radial arm component I also worked with Alayah and Lakshmi. We had to design something that would hold the rotating motor and securely connect it to the linear arm. The way our two motor mechanism works is that the first motor rotates the linear arm, and the second motor moves our 3D printed piece holding the batter tube along the linear arm.

2.2 This component took the longest for us to design because it was connecting multiple parts of our machine and had to be very specifically designed so that it cleared the scaffolding and the motors attached to the arms. We modified one of Quentin and Jake's designs in order to fit our model.

2.3 Unfortunately after a whole night of designing, modeling and fabricating this piece we found out that Jake and Quentin no longer had the type of belt needed to fit into this component. Another group member adjusted our initial design so that the missing piece was not needed and then created the final component that we used in our machine.

C. GROUP CONSTRUCTION + PRESENTATION

C1. Construction

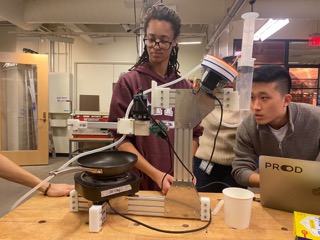

1.1 The Tuesday night before our machine was due our whole section intermittently assembled in the archshop to finalize the construction of our machine and have the programming team, Kevin, Yuchen, and Jakin, test out their code on the machine and calibrate it.

1.2 This last push was all hand on deck and our whole section came together to finish the assembly and test out the code. After MANY hours of debugging our machine worked!!!! Wooohooo!!

C2. Presentation

1.1 Our whole group presented our machine in class and showed a demo of it working. We let Neil draw the design and he opted for a smiley face which our machine made in pancake form!

1.2 Unfortunately the machine is questionably food safe because the tube lived in a dusty woodshop for four days, so you had to enjoy the pancakes at your own risk.

1.3 Overall this week was VERY stressful because it was a LOT to get done in a week but our section is super super proud and excited about what we were able to accomplish. It was great to see us all come together to get this done, and was fun to get to know our group better :)