Introduction

In this week, we have mainly learned how to make big designs (mainly out of wood).

Since we will mainly use OSB material for this week's project (which is not very pretty in appearance), I will make something practical instead of just beautiful.

I have suffered long from not being tall enough to reach staffs on the shelves. Therefore, I'm going to make a standing tool for myself. The objects are very simple:

- Tall but not occupying large space.

- Press-fit and robust at the same time.

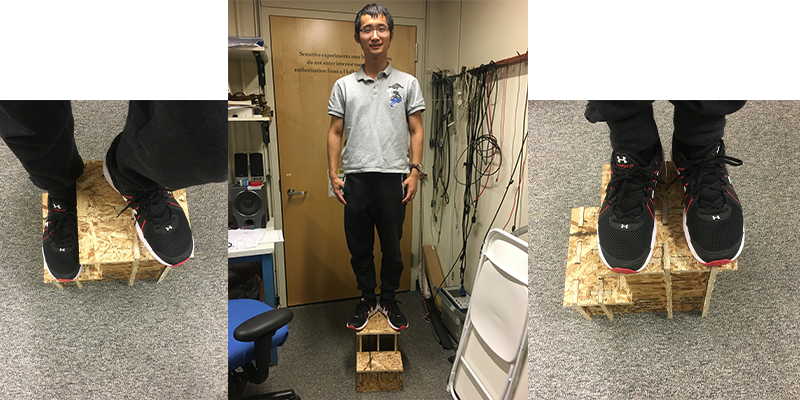

This is an example of standing tools in my lab:

Basically, my standing tool should have two stages, plus the top stage should be wide enough.

Designing of the standing tools

The model is designed in OnShape. All the parts will be assembled in a press-fit design. Actually, I found that among all the skills I've learned in this class, I love press-fit design best!

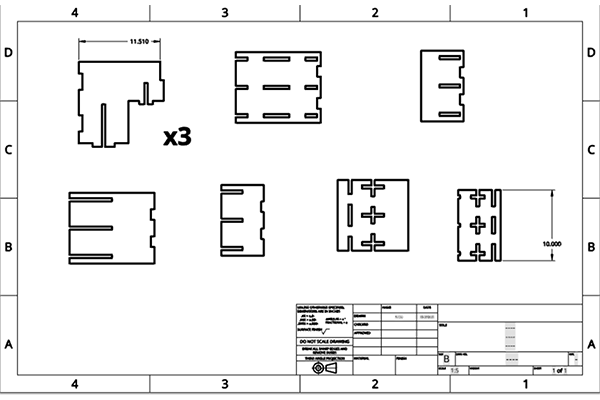

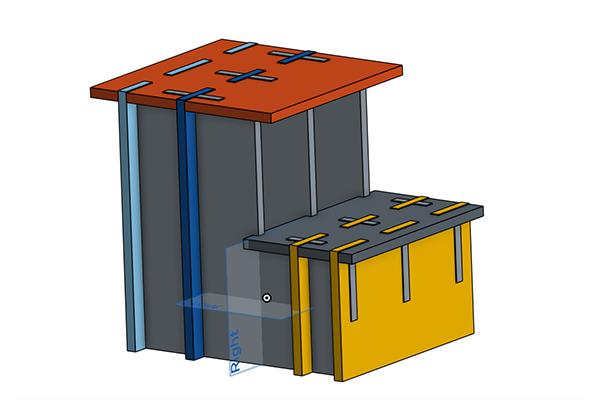

This is the cutting list of my standing tool, and its 3D model:

Notice that there are seven plates in the vertical direction to support weights, which ensures the standing tool is strong enough. The two top plates serve as standing plates as well as big joints in the horizontal direction.

Generating toolpath and test cutting

In generating the toolpath, I have encountered following problems:

- It's not easy to control the width of slots, because even if I have selected Outside Cutting, sometimes the toolpath was generated such that it went outside of the trace for one slot, but went inside for another slot with exactly the same size.

- I also find it's very annoying to adjust the slot size in OnShape. Maybe there is a function called Leaving Offset between Connections that I didn't find?

- In the test cutting, I also found that it's very important to adjut your z-height according to your board thickness before cutting. Otherwise, the tab will possibly be cut away and your parts will move during cutting.

Cutting and final product

This is the picture of machine running.

Three views of my standing tool.

All parts are connected in a press-fit way. All the vertical parts are constraining each other, and the two standing plates lock all the vertical parts tightly. In the last, the two standing plates are held in their position by gravity.

This picture shows that I was standing on the standing tool. The standing tool feels very rigid. It won't shake or deform when I'm standing on it. It's also high enough for me to reach the top of shelves in my lab. I would say I'm pretty satisfied with it.

I have conducted another test to show it's robust enough: