Wildcard Topic: 5-Axis CNC Milling

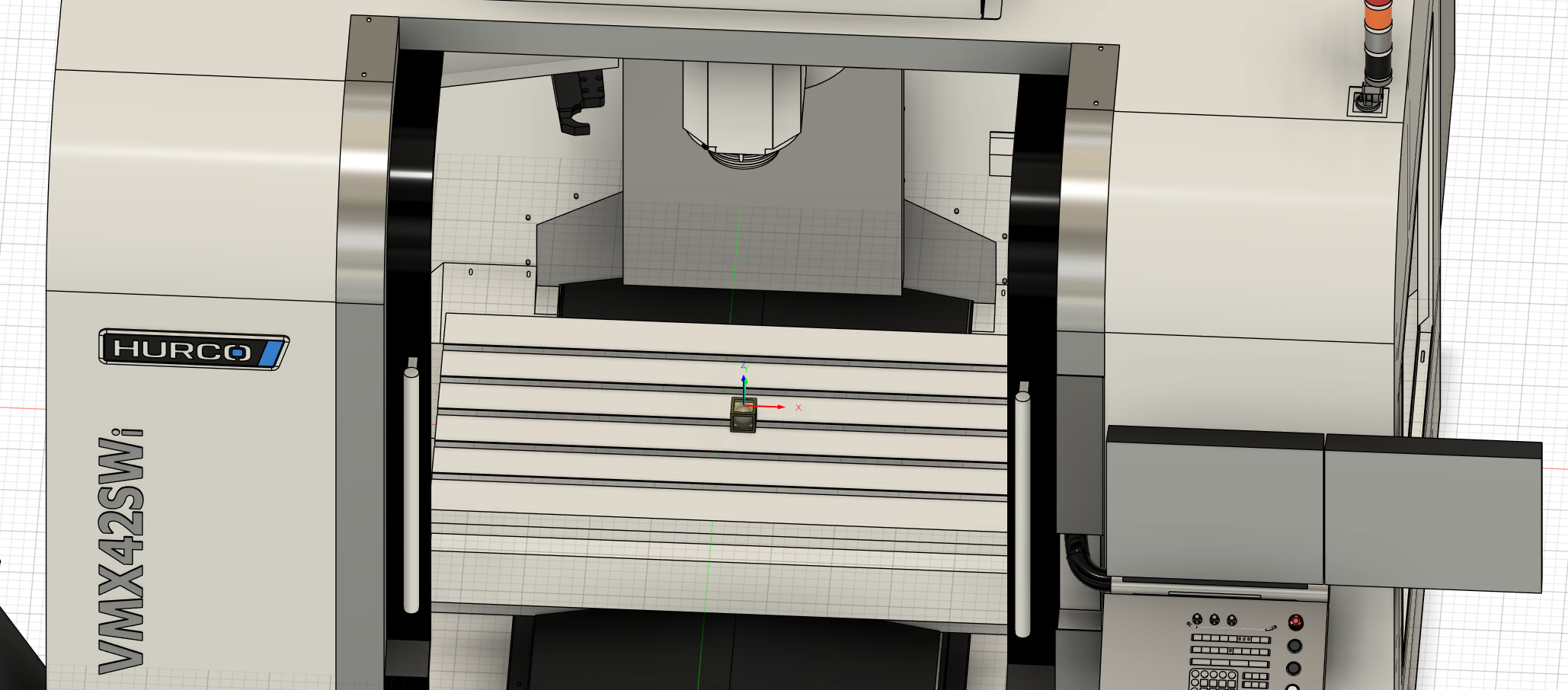

For wildcard week, I elected to learn the 5-axis CNC machine that the CBA section recently acquired: a Hurco VMX42SRTi. The machine is still being commissioned by the shop and course staff, and the operating procedures are still being fine-tuned, but for simple parts we are able to still use the Hurco. The key here is "simple parts." Initially, I was inspired to try and replicate "The Ant", a demo project from the early days of commercial 5-axis CNC. Pictured right, this life-sized ant is a very impressive demonstration of both careful programming and precision machining.

For wildcard week, I elected to learn the 5-axis CNC machine that the CBA section recently acquired: a Hurco VMX42SRTi. The machine is still being commissioned by the shop and course staff, and the operating procedures are still being fine-tuned, but for simple parts we are able to still use the Hurco. The key here is "simple parts." Initially, I was inspired to try and replicate "The Ant", a demo project from the early days of commercial 5-axis CNC. Pictured right, this life-sized ant is a very impressive demonstration of both careful programming and precision machining.

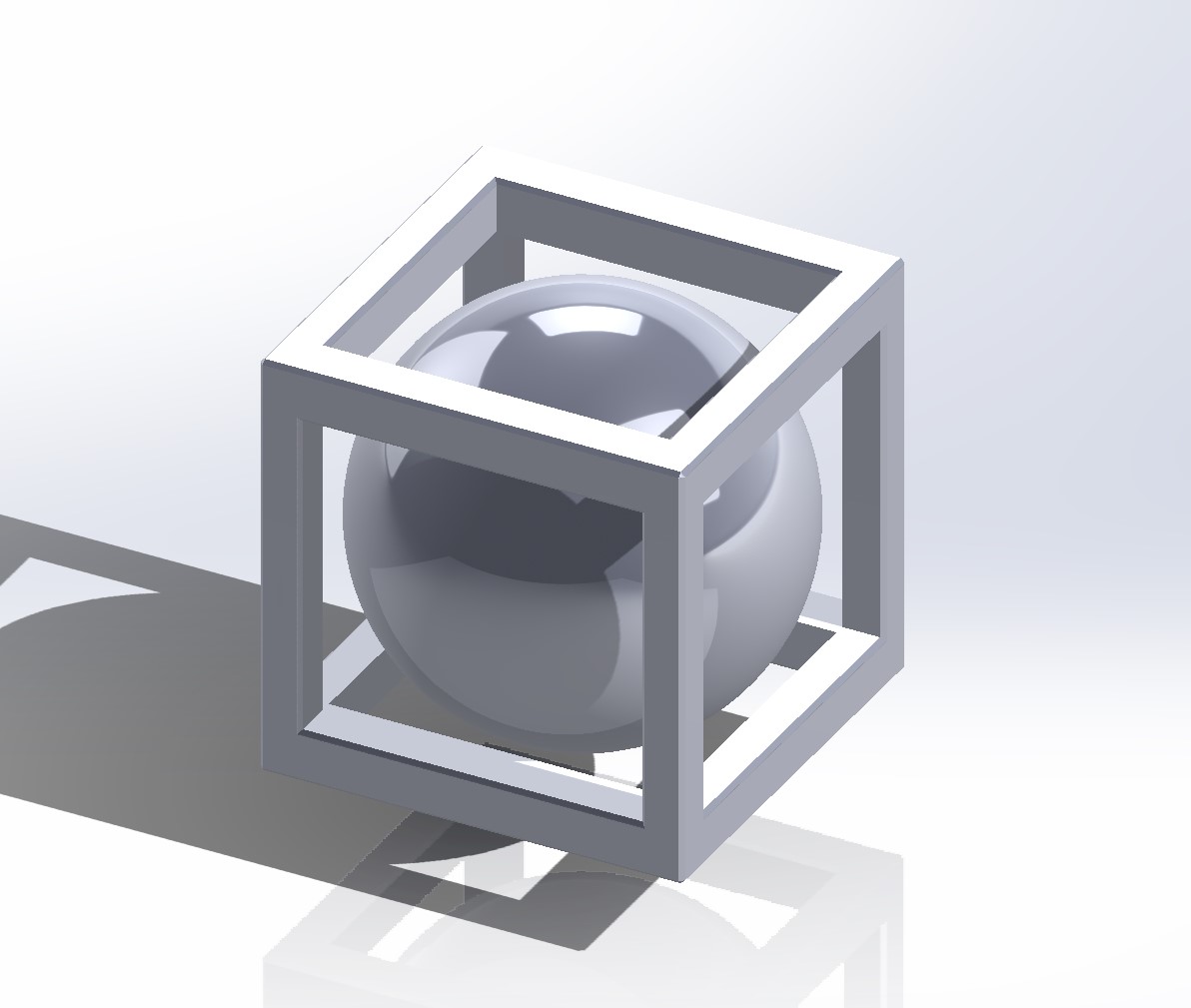

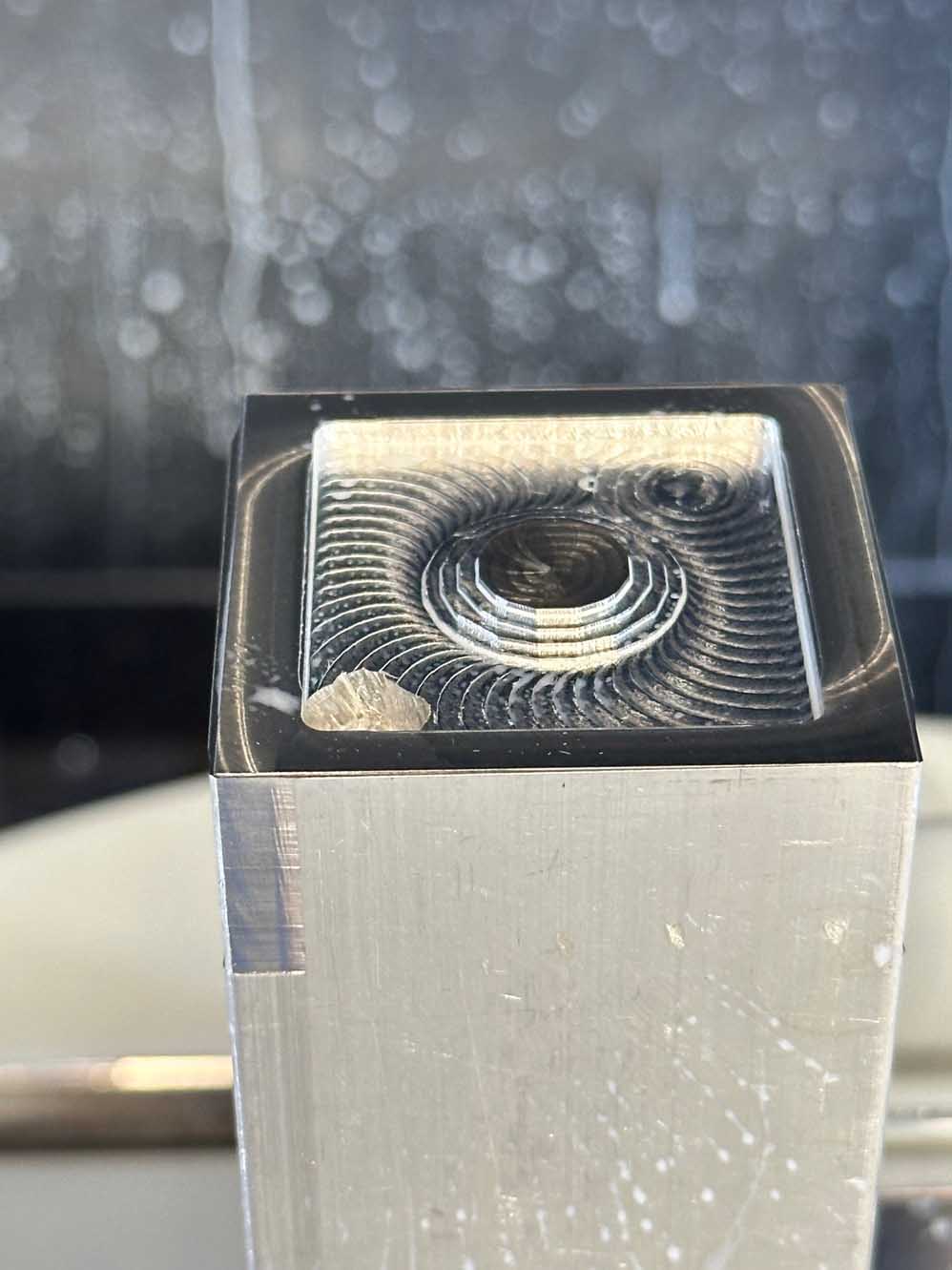

After discussing the job with Marcello, it became clear that making "The Ant" or any insect-like variation (I was considering a dragonfly) would be out of scope for the machine with our current understanding of its operational modalities and the time constraints of the machine this week. As such, I elected to mill something more attainable for the week: a miller's cube. The concept for the miller's cube is simple: the part is a wireframe cube contining a sphere of diameter equal to the cubes side length. I went to grabcad for this design to save some time, and found a perfect model that was dimesioned exactly to me needs as well - what luck. Below is the STEP file for the miller's cube.

The strategy here is that each face would be individually machined and the cube re-registered and moved. The rationale was that the machine currently struggled with overhangs in the part. Essentially, this machine has become a very facy 3-axis CNC with the ability to do finishing passes in 5 axes. Ain't that just the way. Regardless, learning the machine will be useful as I have seen nearly this exact model at a few of my industry internships, so it will be a useful skill to have.

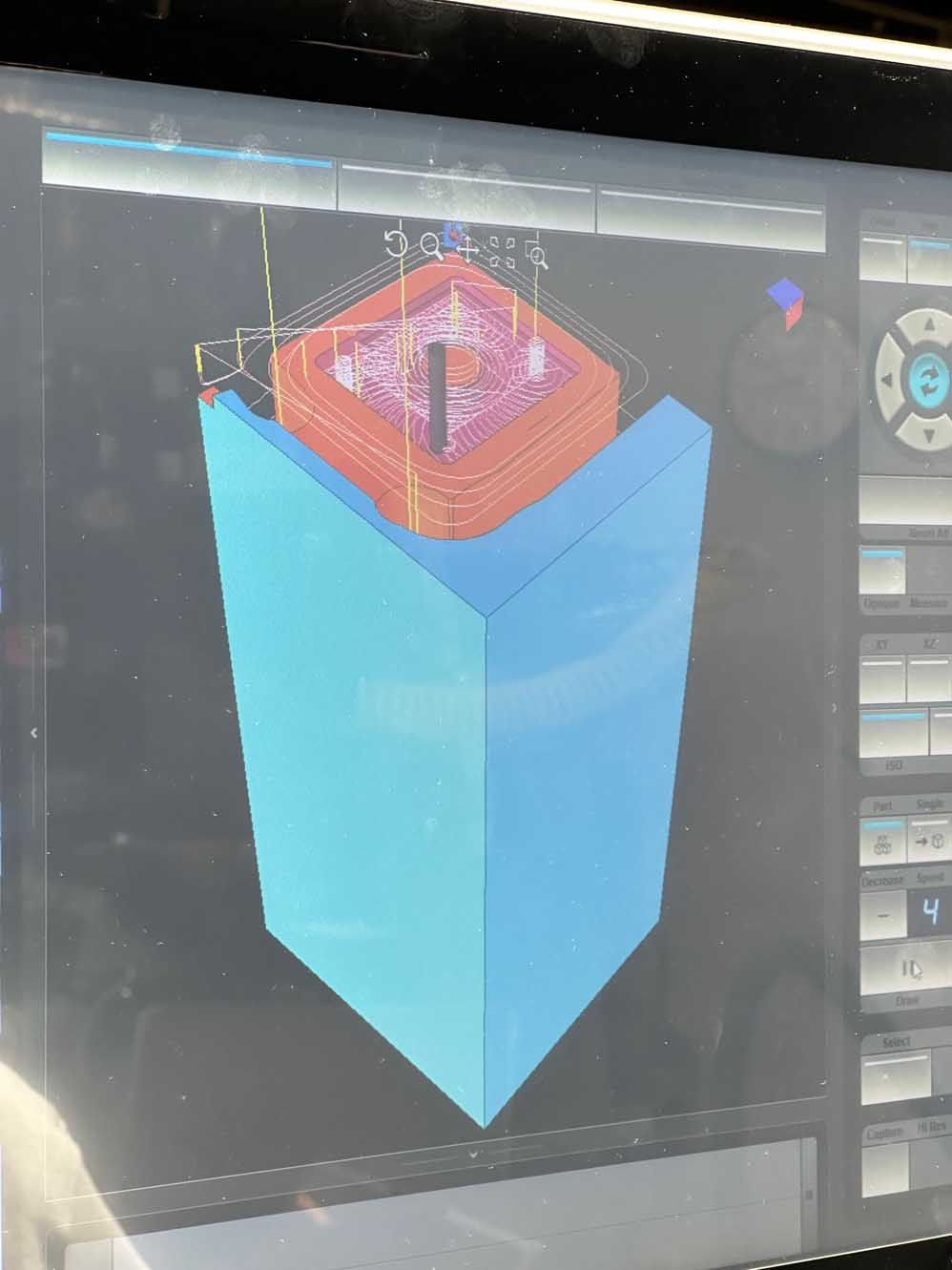

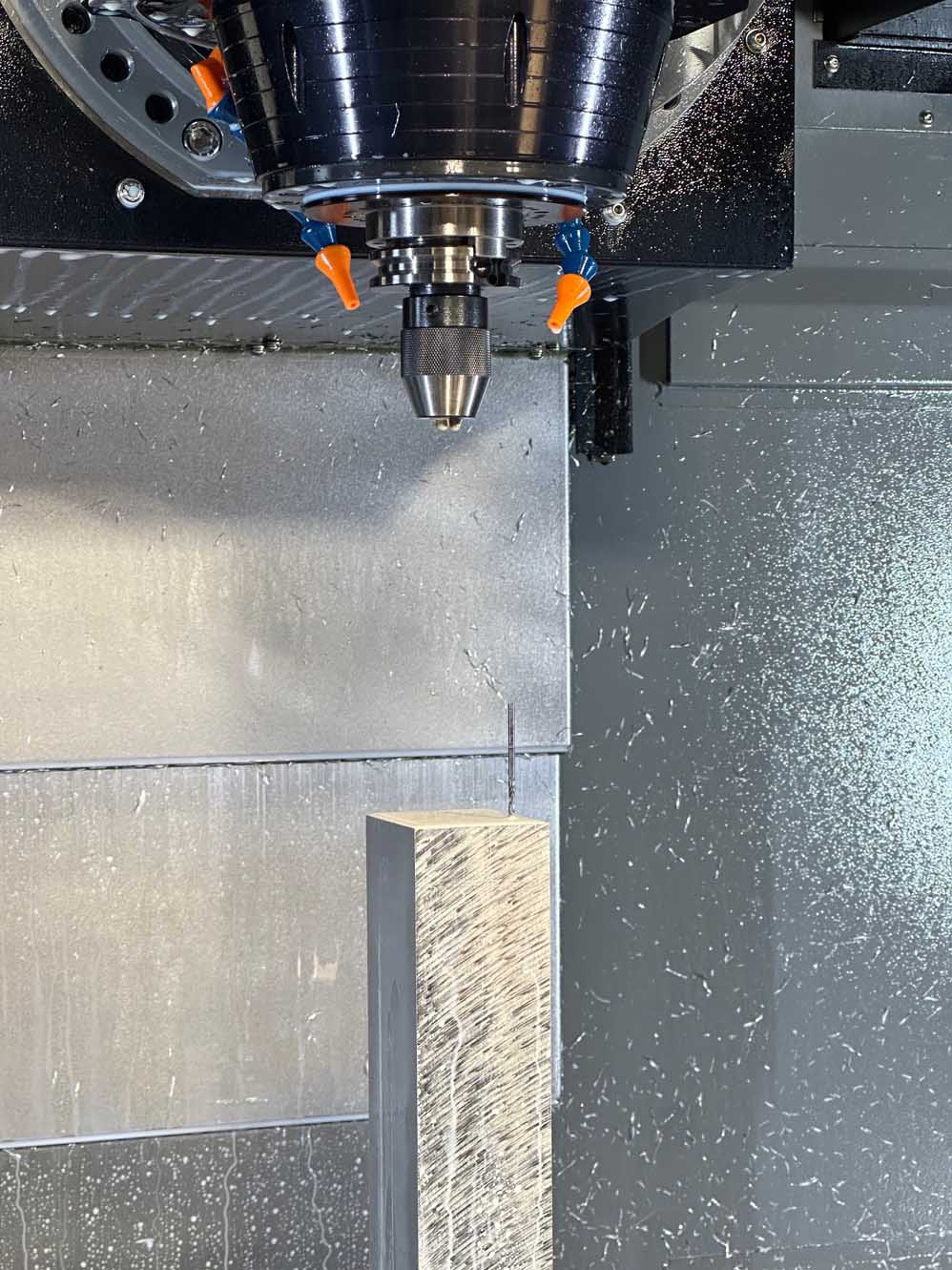

The part was taken to FusionCAM for the initial milling operation. A couple of 3D adaptive clearing operations were planned and then some 5-axis finishing passes. Below is the FusionCAM that was imported to the Hurco for a single face of the millers cube.

This is when the delays started to happen. I quickly learned that this is not a fast machine by any measure. Setup takes an hour, and the milling operations are run at ~10% of the file specification to avoid breaking endmills. This was tricky to navigate since the part was supposed to take 30 min initially, but when running the majority of the path at 10% (and at times 2%) feedrate, the total time was closer to 3 hours.

Several endmills broke along the way which meant restarting the job a few times over. All of this is to say that a single face of the cube took roughly 7 hours to machine. I quickly had to descope the project to be just the single face for this week, and finish the cube next semester as a passion project (although I can now say I know how to drive the Hurco!) but thats just how it goes sometimes.

After completing the assignment, I think I have settled on the wording for a 5-axis CNC homework: Subtractively manufacture something (~cm3) that requires a machine to utilize more than 3 degrees of freedom.

Below is both my finished face of the cube, and proof that I used all 5 axes of the Hurco, in addition to all of the files for this week.